Breathable fabric can power small electronic devices

One of the more futuristic applications of this technology might be electrified clothing, according to the researchers.

4th August 2017

Innovation in Textiles

|

Nashville, TN

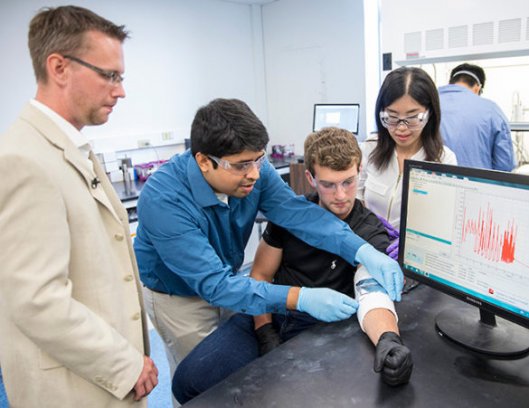

Vanderbilt University’s Nanomaterials and Energy Devices Laboratory has developed a new, ultrathin energy harvesting system that has the potential to power your cell phone, fitness tracker and other personal electronic devices as you walk, wave and even when you are sitting down.

Based on battery technology and made from layers of black phosphorus that are only a few atoms thick, the new device generates small amounts of electricity when it is bent or pressed even at the extremely low frequencies characteristic of human motion. “In the future, I expect that we will all become charging depots for our personal devices by pulling energy directly from our motions and the environment,” said Assistant Professor of Mechanical Engineering Cary Pint, who directed the research.

The new energy harvesting system is described in a paper titled Ultralow Frequency Electrochemical Mechanical Strain Energy Harvester using 2D Black Phosphorus Nanosheets published on 21 July online by the journal ACS Energy Letters. “This is timely and exciting research given the growth of wearable devices such as exoskeletons and smart clothing,” said Karl Zelik, assistant professor of mechanical and biomedical engineering at Vanderbilt.

Currently, there is a tremendous amount of research aimed at discovering effective ways to tap ambient energy sources. “Compared to the other approaches designed to harvest energy from human motion, our method has two fundamental advantages,” said Pint. “The materials are atomically thin and small enough to be impregnated into textiles without affecting the fabric’s look or feel and it can extract energy from movements that are slower than 10 Hertz—10 cycles per second—over the whole low-frequency window of movements corresponding to human motion.”

The Vanderbilt lab’s ultrathin energy harvester is based on the group’s research on advanced battery systems. Over the past three years, the team has explored the fundamental response of battery materials to bending and stretching. They were the first to demonstrate experimentally that the operating voltage changes when battery materials are placed under stress. Under tension, the voltage rises and under compression, it drops.

The team collaborated with Greg Walker, associate professor of mechanical engineering, who used computer models to validate these observations for lithium battery materials. These observations led Pint’s team to reconstruct the battery with both positive and negative electrodes made from the same material. Although this prevents the device from storing energy, it allows it to fully exploit the voltage changes caused by bending and twisting and so produce significant amounts of electrical current in response to human motions.

The lab’s initial studies were published in 2016. They were further inspired by a parallel breakthrough by a group at Massachusetts Institute of Technology. In response, the Vanderbilt researchers decided to go as thin as possible by using black phosphorus nanosheets: A material has become the latest darling of the 2D materials research community because of its attractive electrical, optical and electrochemical properties.

Because the basic building blocks of the harvester are about 1/5000th the thickness of a human hair, the engineers can make their devices as thin or as thick as needed for specific applications. They have found that bending their prototype devices produces as much as 40 microwatts per square foot and can sustain current generation over the full duration of movements as slow as 0.01 Hertz, one cycle every 100 seconds.

The researchers acknowledge that one of the challenges they face is the relatively low voltage that their device produces. It is in the millivolt range. However, they are applying their insights of the process to step up the voltage. They are also exploring the design of electrical components, like LCD displays, that operate at lower than normal voltages.

One of the more futuristic applications of this technology might be electrified clothing, according to the researchers. It could power clothes impregnated with liquid crystal displays that allow wearers to change colours and patterns with a swipe on their smartphone.

“We are already measuring performance within the ballpark for the power requirement for a medium-sized low-power LCD display when scaling the performance to thickness and areas of the clothes we wear,” Pint said.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more