Registration now open for Techtextil 2019

According to the company, Outlast is the only supplier in the textile industry able to offer various PCM possibilities.

11th March 2015

Innovation in Textiles

|

Heidenheim

Outlast Technologies, a market leader for temperature regulating phase change materials (PCMs), will present the complete PCM spectrum for more transparency at the upcoming Techtextil trade fair for technical textiles and nonwovens that takes place from 4-7 May in Frankfurt.

Outlast is best known for its presence in the bedding industry (PCMs for mattresses, duvets, mattress protectors/toppers, pillows, and more), but is also very active in the apparel (outdoor, sportswear, underwear, protective wear), footwear (shoes, socks, insoles), and accessory industry.

But Outlast has also devoted a lot of time researching new markets where the technology can be utilized – the newest development being in the electronics industry.

According to the company, Outlast is the only supplier in the textile industry able to offer various PCM possibilities.

In the past years, the company released the PCM viscose fibre, following the development of the first PCM polyester fibre. This presented a new opportunity for filling materials, which are mostly used for bedding, but can also be utilized for apparel.

PCMs can be structured in the following categories:

Outlast technology was originally developed for NASA to protect astronauts from temperature fluctuations in space.

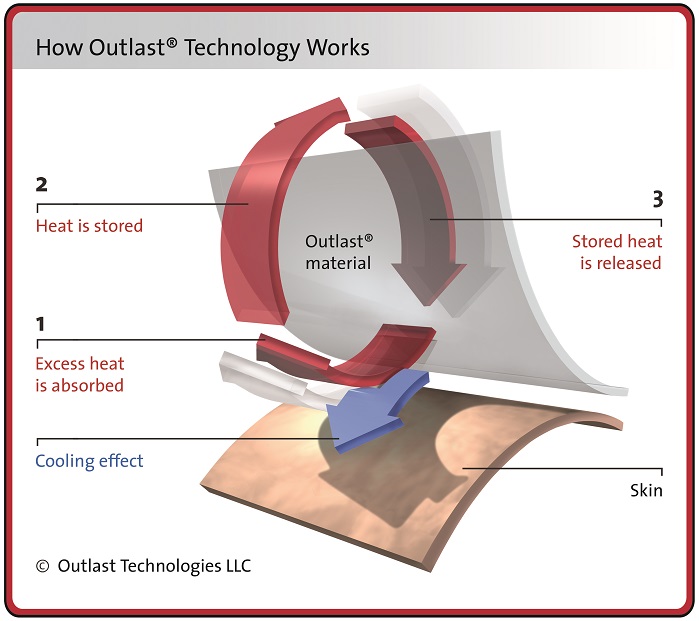

Outlast technology utilizes phase change materials (PCM) that absorb, store and release heat for optimal thermal comfort. The PCMs have the capacity to absorb, store and release excess heat. This gives any product containing Outlast technology the ability to continually regulate the skin’s microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more