First for flax in Dutch viaduct

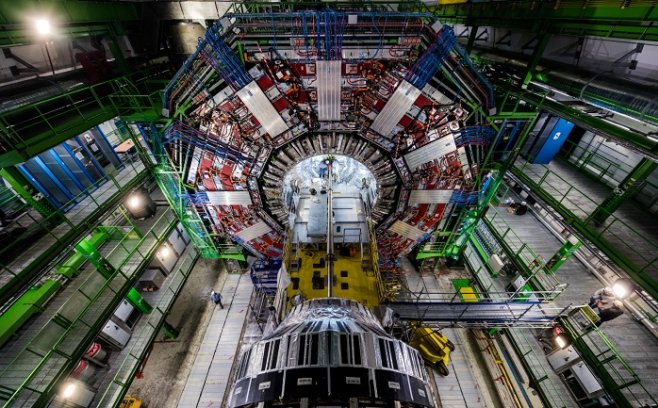

Carbon fibre components have completed 9 years of service at CERN's Large Hadron Collider (LHC) particle accelerator in Geneva.

18th December 2017

Innovation in Textiles

|

Runcorn

“We are very satisfied with the high level of technology and development support offered by Exel Composites,” commented Antti Onnela, CMS Tracker Project Engineer at CERN. “We had quite challenging requirements for these composite structures and earlier laminated versions did not meet them. Exel developed the needed thin-walled U-profiles that turned out to be technically superior, but also more economical thanks to the production process that minimised the wastage of expensive carbon fibres. After nine years in service in the CMS the Exel parts continue performing as flawlessly as in the beginning.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more