SGL acquires BMW’s interest in joint venture

The carbon fibre material for the hybrid roof frame construction comes from SGL Group being involved in various stages of the value chain.

24th April 2015

Innovation in Textiles

|

Wiesbaden

A few years ago, carbon fibre reinforced plastics (CFRP) in the automotive industry were mostly used as design elements. Later, CFRP was applied in structural components in special edition models and luxury sports vehicles produced in small numbers.

Especially driven by the BMW i3 and i8 models, CFRP had a breakthrough in automotive serial production. With its application in the new BMW 7 series, the material is now for the first time making its way into large-scale production in the premium car segment.

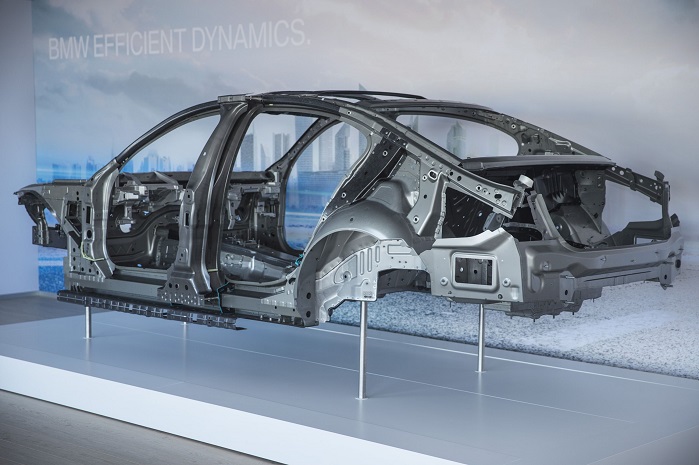

The latest BMW 7 series featuring carbon fibre preforms by SGL Group, the leading manufacturer of carbon fibre and composite products, was introduced last week. These were built using innovative hybrid chassis construction method, referred to as Carbon Core.

This application of CFRP is said to lead to substantial weight reduction and also help to further enhance the driving dynamics by lowering the vehicle’s centre of gravity. Overall, the new 7 series generation is up to 130 kilograms lighter than the previous one, despite significantly improved comfort and safety features.

“The use of our carbon fibre based products in the new BMW 7 series is another milestone in the large-scale serial application of carbon materials in the automotive industry,” commented Jürgen Köhler, CEO of SGL Group.

“This project also further underlines the great potential of carbon fibres for innovative automobile applications and demonstrates that SGL Group's long-term development of the entire value chain is paying off.”

The carbon fibre material for the hybrid roof frame construction comes from SGL Group being involved in various stages of the value chain. The carbon fibres will be produced by the joint venture SGL Automotive Carbon Fibers (SGL ACF) in Moses Lake in the US State of Washington. The required production capacities for the carbon fibres were built up in recent years.

As a next step in the value chain specific preforms will be manufactured using the fibres in fully automated textile production processes. The preforms are then delivered directly to the BMW Group for CFRP parts manufacture. Following the BMW i models, the overall volume of carbon fibre used in the new BMW 7 series makes this the second largest serial production project industry-wide.

In addition to the carbon fibre products for the roof frame, SGL Group also delivers carbon fibre fabrics and recycling materials, manufactured at the SGL ACF site in Wackersdorf. Developed in cooperation with BMW, these carbon fibre recycling products will be used in the C-pillar and in the trunk compartment partition.

“The innovation partnership between BMW Group and SGL Group has started 15 years ago and had its first highlight with the utilization of carbon fibres and carbon fibre fabrics in the BMW i models,” commented Andreas Wüllner, Head of the Business Unit Carbon Fibers & Composite Materials of SGL Group and Managing Director of SGL ACF.

“With the introduction of the hybrid construction method “Carbon Core” for the passenger cell of the new BMW 7 Series, the cooperation is now being developed further”.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more