EDANA opens registration for Outlook Asia 2018

Population figures in Asia are increasing all the time, and are being accompanied in many countries by enormous growth in the nonwovens markets. Here, Groz-Beckert, a company with 1500 different product types, explains how suppliers of mechanically bonded nonwovens can share in the success of nonwovens in Asia.

15th June 2012

Innovation in Textiles

|

Albstadt

Population figures in Asia are increasing all the time, and are being accompanied in many countries by enormous growth in the nonwovens markets. Here, Groz-Beckert, a company with 1500 different product types, explains how suppliers of mechanically bonded nonwovens can share in the success of nonwovens in Asia.

Population figures in Asia are increasing all the time, and are being accompanied in many countries by enormous growth in the nonwovens markets. Here, Groz-Beckert, a company with 1500 different product types, explains how suppliers of mechanically bonded nonwovens can share in the success of nonwovens in Asia.

“Asia is the world's biggest continent, comprising 45 countries and extending from the equator to the Arctic Circle. It covers an area of more than 44.5 million square meters – that is, around one third of the worldwide land mass. Alongside many poorer countries it also contains some of the wealthiest lands in the world. The continent's population numbers roughly four billion – equivalent to around 60% of all the people in the world.

The world's population is continuing to grow, and on average is becoming ever older. This growth is of course driving urbanization, especially in Asia. Today almost 50% of human beings on this planet live in cities.

Over the next 40 years, that figure will rise to 70% – an enormous challenge, on many levels. Secure food and power supplies, availability of affordable housing, and effective national and international transport connections are just a few examples here.

A special challenge will be to reduce energy requirements, so as to maintain living standards in cities in the future as well. Cities currently account for around 80% of the planet's total CO2 emissions.

The growth in Asia presents the nonwovens industry with great opportunities. Worldwide, cities are investing around 2 billion Euro in their infrastructure – so the hope is that there will be steadily increasing demand for geotextiles.

The fight to reduce CO2 emissions will also require the increased production of filters. There are further areas of application too: since an increasing number of people live in areas without sufficient drinking water, high growth rates for the drinking-water filter sector are also expected.

With its Technology and Development Center (TEZ) Groz-Beckert offers not only its German customers but all its customers worldwide the opportunity to either initiate such products or to further develop them.

Groz-Beckert is well positioned to cater to the steadily increasing demand for nonwovens articles in the Asian market. In addition to its production plants in China and India, which have been in existence for several years now and have been continuously extended and optimized, since 2011 the company has had a new production site in Vietnam. With a total of 52 agencies across Asia, Groz-Beckert is well placed for the future.

Moreover, German employees are being sent to Asia on a continuous basis, and especially China. In this way, qualified application technicians can answer customers' questions and provide recommendations on-site. The employees of Groz-Beckert in Asia naturally benefit from exchanges with partners and the transfer of expertise.

The most important countries so far in the nonwovens sector for Groz-Beckert are China, Japan, South Korea and India. The main areas of application range from artificial leather, filter products and paper-machine felts to automotive felts, geotextiles, floor coverings and felts for insulation.

In Japan, growth in the nonwovens industry is beginning to stagnate. The products from Japan are primarily impressive for their outstandingly high quality. Fine and ultrafine gauge needles with rounded barbs are primarily used here (RF and HL), providing a very good and even product surface while achieving optimal gentleness to fibers at the same time.

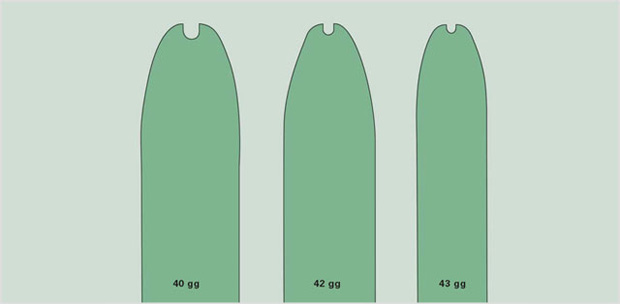

In addition to barb needles so-called structuring needles are used – i.e. fork and crown needles. They are especially suitable wherever quality requirements are extremely high, e.g. the automotive sector. Groz-Beckert is the only manufacturer on the market able to provide a structuring needle in the fine gauge 43 gauge which despite its filigree design is stable enough for the manufacture of the highest-quality products.

Groz-Beckert also offers needles with special coatings which not only prevent corrosion but also lengthen needle service life. As a full assortment provider Groz-Beckert can of course deliver needle types for less demanding applications as well. This involves needles with so-called conventional barbs, which have also proven themselves to be very suitable for highly specialized and technically demanding applications. Products manufactured in this way include synthetic leather and felts for automotive interiors.

GEBECON needles are a further special design in the Groz-Beckert range. Due to the conical working part – and also, depending on the design, the equally conical transition area – they have higher needle stability while retaining acceptable product surfaces. These needles are primarily for use in pre-needling machines for the fine and ultrafine fibre product sector.

In China, increasing use is being made today of recycled PET fibers. Here Groz-Beckert offers special needle types with adapted needle points. These largely prevent so-called ‘fork formation’ on the points of the felting needles, which otherwise occurs on less pure, recycled fibers.

A further type of needle is the teardrop-shaped needle. These have only one edge equipped with barbs, and otherwise have a fully rounded working part cross-section. Teardrop shaped needles are used to great advantage in the production of paper-machine felts.

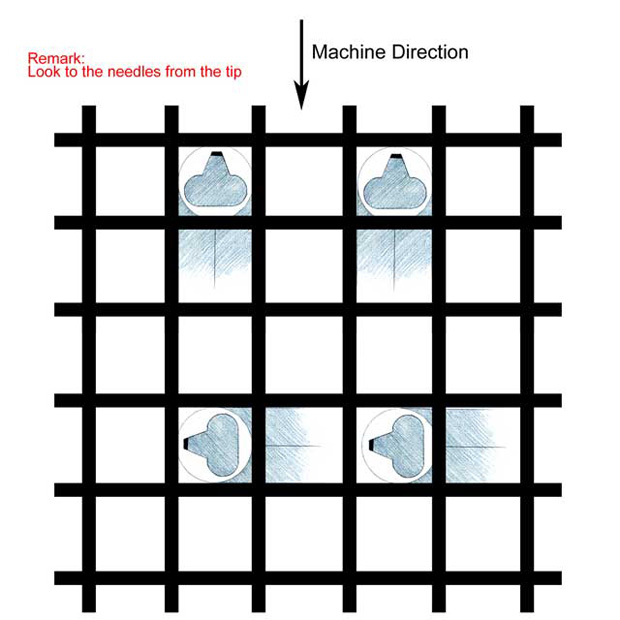

The rounded working part and three-dimensionally rounded barbs (HL) achieve optimal gentleness on both the fibers as well as the base material in the felt. This means that the required high level of tensile strength in the paper-machine felt that is necessary for the application can be successfully achieved. During needling, this needle type also allows for a defined alignment of the barbs in the MD as well as the CD direction.

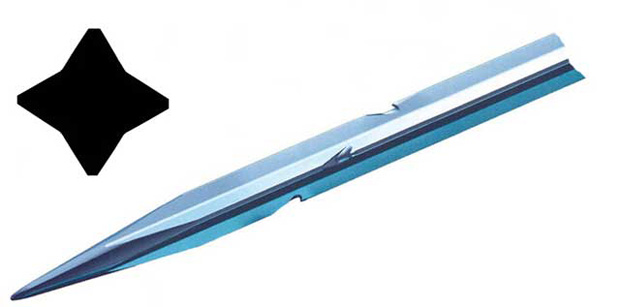

In the near future Groz-Beckert will also be continuing to offer a further needle geometry that causes lower penetration force while retaining the same level of efficiency, thereby preventing stress on the machine equipment. The special feature of this needle is that the edge bearing the barbs is rectangular. This increases the looping angle of the fibers and, as a result, the needling efficiency. This type of needle is marketed under the name EcoStar.

In addition to selection of a suitable needle type, handling of the needles as well as the right exchange cycles are of crucial importance where product quality is concerned. Customers interested in overall optimization of their product receive support from Groz-Beckert in the form of useful suggestions as well as specific recommendations with regard to the introduction of a needle rotation system.

For insulation felts made from inorganic fibers such as glass, ceramic or mineral wool place special requirements on needles, because these types of fibre generally display very low elongation and can thus break quite quickly.

Moreover, needles used in the processing of inorganic fibers suffer an extremely high degree of wear. This is why needles that have undergone metallurgical treatment are the product of choice here. This special coating is marketed by Groz-Beckert under the brand-name of GEBEDUR II.

Sometimes, very special needles equipped with an ‘open barb’ are used to successfully redirect numerous fibers into a vertical position. In the case of voluminous insulation nonwovens, combinations of needles can also be employed. These gradually taper towards the end in order to achieve complete needling and to reduce needle breakage.

As a full-assortment provider, Groz-Beckert also supplies the large geotextiles sector with suitable, specially designed needles. In some parts of the geotextile range, customers work with Tri STAR and Cross STAR needles, since in geotextiles the surface plays a secondary role while products require high tensile strength.

Both needle types are distinctive for their extremely high efficiency. The Tri STAR needles feature concave flanks, while the Cross STAR needles have an additional fourth edge.

In the jetstrips sector for hydroentanglement products, Asia is the world's largest market. Continuing growth is primarily due to the hygiene sector, the main centres of which are located in the provinces of Shanghai, Fujian, Haian and the region around the Yangtse Delta.

In this product segment, too, Groz-Beckert has successfully gained a foothold in the Asian market. One reason for this is comprehensive customer support – just as with the needles. Materials are analyzed and optimized so that the performance specifications of the jetstrips can be continuously improved.

Not least of all, Groz-Beckert offers information documentation on all the important aspects of hydroentanglement, from the ideal way to clean jetstrips and special treatment for increasing scratch resistance and service life to technical service and process water analysis. Find out about this in more detail here.”

Source: Groz-Beckert

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more