ALMACO promotes event at Petrobras

Expanded access to Torun’s UNESCO World Heritage Site old town.

31st January 2022

Innovation in Textiles

|

Hofheim, Germany

Fibrolux, a leader in the development and manufacture of pultruded composites based in Hofheim, Germany, has completed its largest civil engineering project to date – the supply of more than 16 kilometres of a large-scale custom fibreglass pultrusion to Poland.

The special composites have enabled the refurbishment of the kilometre-long Marshal Jozef Pilsudski Bridge in the city of Torun with double width pedestrian and cycling walkways.

As part of an extensive bridge upgrade programme to provide additional capacity and improve safety by moving cyclists away from the road carriageways, Fibrolux produced a pultruded composite slab solution for the new walkways.

Originally constructed in Münsterwalde, Germany in 1909 as a road and railway crossing, the main bridge structure was disassembled and moved to Torun in north-central Poland in 1934. The Marshal Jozef Pilsudski Bridge links the southern part of town with Torun’s UNESCO World Heritage Site old town.

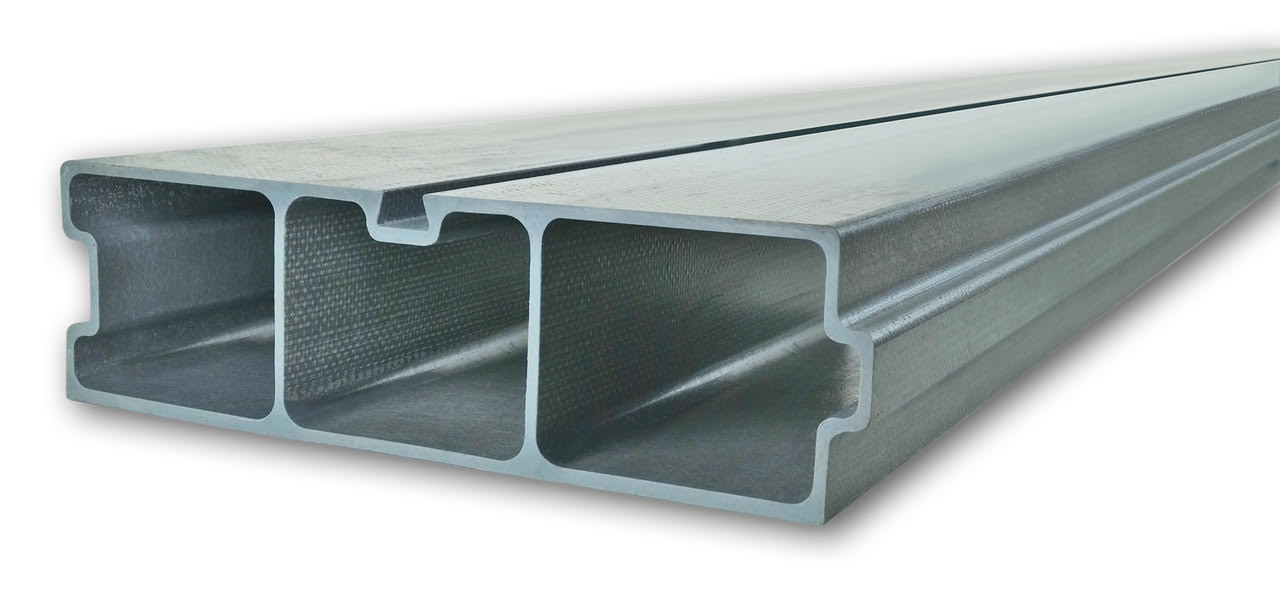

The bridge concept, an interlocking walkway deck panel formed from eight massive triple cavity pultruded profiles 500mm x 150mm in section, allowed the walkways on each side of the bridge to be expanded from 2m to 4.5m in width, creating safe space for cyclists. With the existing bridge structure unable to support the weight of wider steel walkways, the lightweight glass fibre composite structure delivered the required capacity upgrade as well as providing a low maintenance, cost effective solution for the project engineers.

Custom die

Fibrolux created a custom die for the new super-sized bridge profile before launching production of the 16km of profiles using a combination of assembled rovings and mats. The pultruded sections were delivered to site cut to length, assembled using custom stainless-steel fasteners, and then given an anti-slip coating, creating panels approximately 4m x 10m that could be lifted into position using a small crane due to the low weight of the pultruded sections. The assembly was carried out by the Polish company NTI Sp. z o.o. Nowoczesne Techniki Instalacyjne.

Fibrolux will also supply a range of standard fibreglass pultruded sections that will directly fasten to the composite walkway slabs and will be used to support the rainwater drainage system for the refurbished bridge.

“The Marshal Jozef Pilsudski Bridge project is a fantastic showcase for pultruded composites in civil engineering,” said Sebastien Mehrtens, Business Development Director, Fibrolux GmbH. “Longer than nine football pitches, the new walkways highlight not only the weight saving and durability benefits of composites, but also the cost and time on site advantages of a large scale Fibrolux custom profile design.”

Installation of the first phase of the walkway on one side of the bridge was completed in spring 2021. The second phase, that doubled previous capacity of the bridge for pedestrians and cyclists, was completed in December 2021.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more