Global expansion for Loepfe Brothers

Innovation in Textiles talks to Dr Andreas Raps, CEO, Freudenberg Performance Materials.

7th May 2024

Innovation in Textiles

|

Weinheim, Germany

Innovation in Textiles: What were your immediate priorities in becoming Performance Materials CEO in November last year?

Dr Andreas Raps: I have been with the company for twenty years now at various business groups and for me, the success of Freudenberg is very much down to listening to the customer and anticipating the industry’s needs. The company celebrates its 175th anniversary this year and would not have existed for such a long time if that wasn’t the case.

IIT: Freudenberg Group as a whole reported record turnover and earnings for 2023, how was it for Performance Materials?

AR: Overall, it was a reasonable year but there were challenges for some segments, mainly due to geopolitical developments beyond the company’s control, and also rising interest rates that led to investment hesitation. As we all know, the global building and construction industry was particularly affected.

IIT: What were the bright spots from your differing segments in 2023?

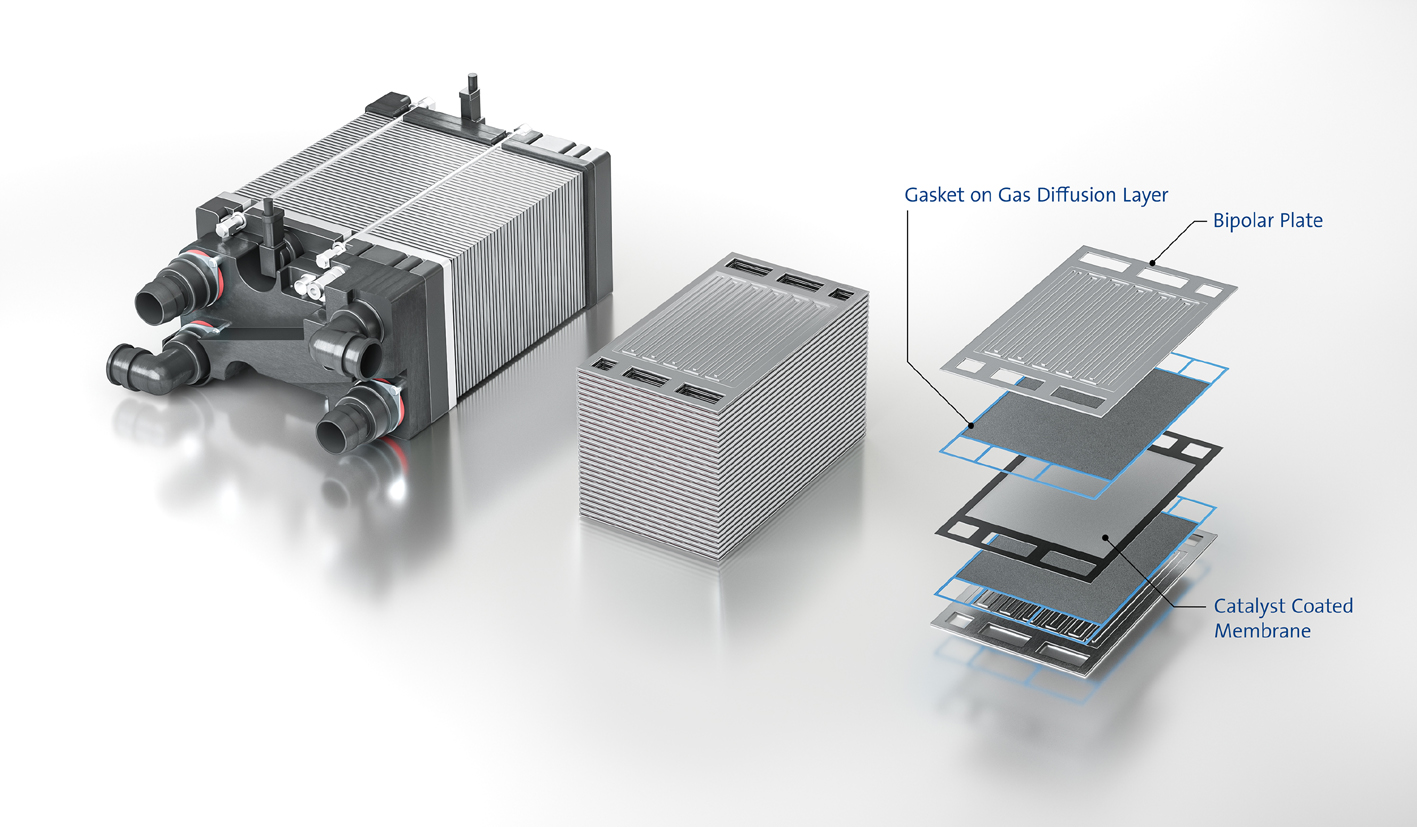

AR: Our business with gas diffusion layers (GDLs) for fuel cells remained high and here, we have an outstanding proposition for the market. GDLs are a critical component of fuel cells which simply won’t work without them. We started our journey more than 20 years ago, so we have built up outstanding expertise in this field and we produce the GDLs fully inhouse on an industrial scale, which enables us to work together with major customers in this industry. We are now ready for our next step in building up a global production footprint, in accordance with our general “local for local” approach.

Our healthcare and condensation control businesses also performed well in 2023.

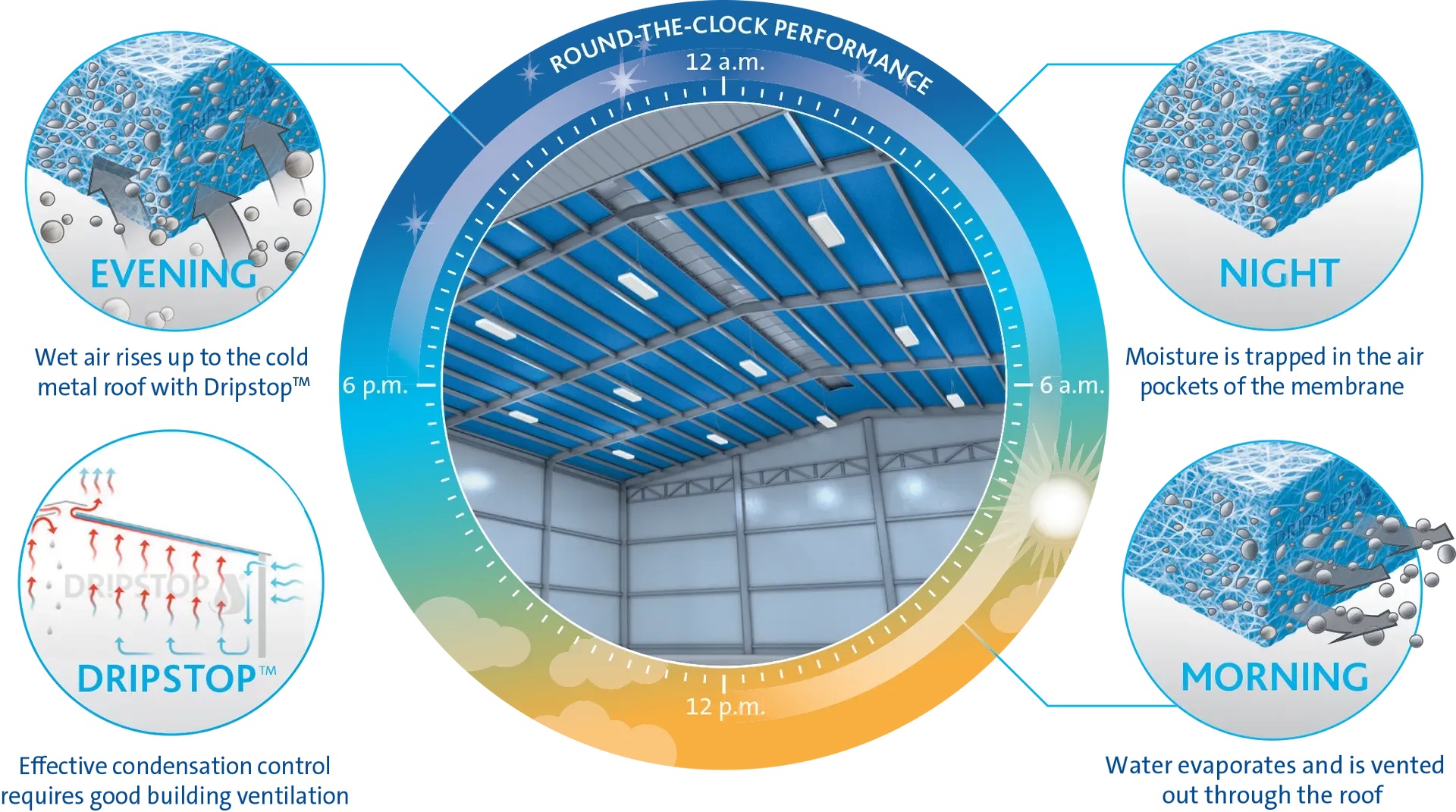

I’m very pleased with the introduction of Dripstop, our latest anti-condensation membrane, to the market. It provides a simpler and more economical way of controlling condensation in metal roofs, so it’s particularly good for barns and animal housing. It has a wonderful acoustic effect and generally creates a much cosier atmosphere.

IIT: Do you see much change in 2024?

AR: The beginning of 2024 has been challenging within a demanding environment for most of our segments, but now we anticipate something of an upturn in the second half of this year. It’s a big advantage that we don’t think in quarters like public listed companies and we stick to our guiding principles which are long-term oriented. This contributes to Freudenberg being a stable, healthy company.

IIT: What investments do you have planned this year?

AR: We are in the process of installing two new lines for our Apparel business, the first in Vietnam to better serve customers in South-East Asia and a second in India, a market which is currently booming and where we have been already producing for decades. We are also making many smaller investments in renewing and upgrading existing lines, with a strong focus on sustainability.

IIT: Waste clothing cannot be landfilled or incinerated from 2025 in the EU. Is this an opportunity for you?

AR: The trend is our friend, and we can drive it! We provide added value to our customers for their sustainability requirements.

Having pioneered PET recycling in the 1990s, we have a proven track record in developing advanced sustainable solutions. We are now recycling some 45 million PET bottles back into flake annually and bringing it all back into our products.

In the latest development, at Techtextil 2024 we displayed a unique jacket produced in cooperation with a major brand that is entirely made from recycled polyamide 6. We provided the wadding but the entire jacket is made from recycled materials – not just the fabrics but also the zippers, velcro fasteners, buttons and stitching.

Together with our customers, however, we must now in general create a higher willingness to pay still higher prices for high performance sustainable solutions on the end consumer side.

IIT: Freudenberg Group is making massive investments in the mobility of the future and established its e-Power Systems Business Group in 2022. How is Performance Materials contributing to this?

AR: As mentioned earlier, our GDLs for both automotive and stationary fuel cells are uniquely superior in the market. In addition, we offer various lightweight products and solutions made from recycled as well as single origin raw materials. Examples are car seat paddings, acoustic pads, and underbody shields for automotive.

As a full solution provider with a global footprint, Freudenberg has unique R&D expertise, and a strong focus on the customer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more