Largest-ever order for Oerlikon Neumag

At the recent ITMA ASIA + CITME, Oerlikon Barmag company focussed on this very promising market with an information showcase.

18th July 2014

Innovation in Textiles

|

Chemnitz, Remscheid, Shanghai

According to Oerlikon Manmade Fibers, carbon fibres as backing material for compound materials are emerging from their niche - estimates from the Victorian Centre for Advanced Materials Manufacturing (VCAMM) say that the demand for carbon fibres will approximately double by 2017.

Only recently, the China Ministry of Industrial & Information Technology published a plan for industrializing the manufacture of carbon fibres in China, Oerlikon reports.

According to the Chinese plan, the output of the top 5 manufacturers in China is to increase by 70% by 2020. Currently, Japan and the USA are the main suppliers of carbon fibres.

Accordingly at the recent ITMA ASIA + CITME trade fair for textile machinery and systems in Shanghai, the group’s Oerlikon Barmag company focussed on this very promising market with an information showcase.

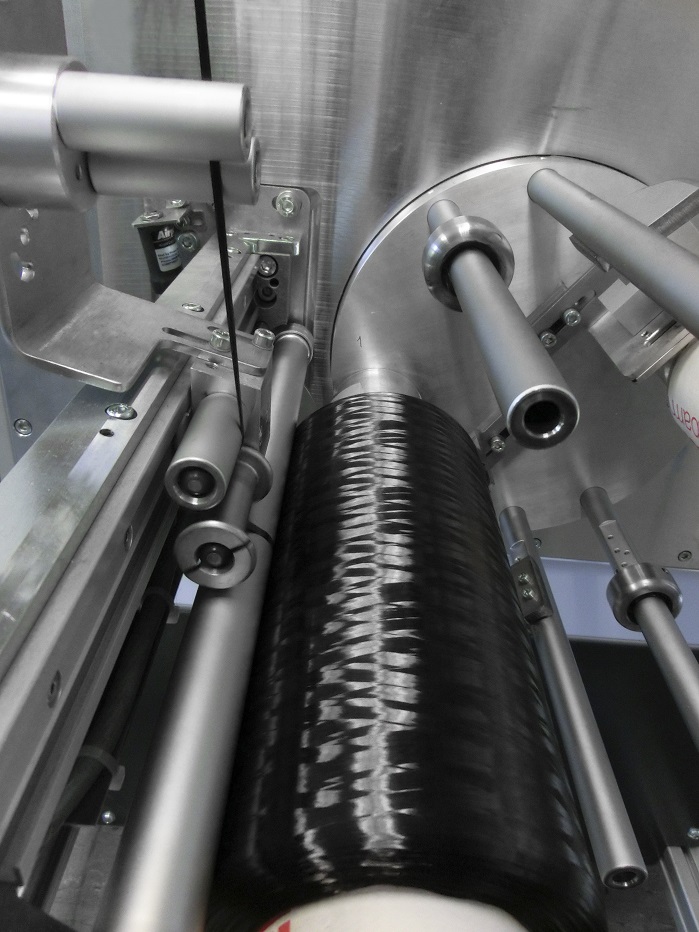

With the automatic WinTrax A-2cop carbon fibre winder, the Chemnitz-based subsidiary of Oerlikon Barmag has a winder in its portfolio that is said to guarantee the economical production of carbon fibres of the very highest quality.

According to the company, the two-cop winder produces packages with perfect package build, identical running length and diameters of up to 310 mm. The resulting higher package weights shorten the tooling times and hence considerably reduce the time and costs for manufacturing compound materials.

As a result of the identical running length of all packages, waste is virtually completely eliminated, Oerlikon says.

Oerlikon Barmag also offers solutions for a large variety of mixing and metering tasks when processing plastics, which are said to actually enable economical production.

“Manufacturers like to deploy the company’s spinning pumps – renowned for their precision – for spinning the composite base materials polyacrylnitrile (PAN) and aramid,” Oerlikon Barmag says.

The majority of common high-performance carbon fibres are today manufactured from polyacrylnitrile and the most significant feature of these fibres is their high modulus with simultaneously very low weight.

This modern material is meanwhile being deployed in many sectors of industry; for instance, in medical technology, in the aerospace industry, in the wind power industry and in the automobile industry, among others.

Oerlikon Manmade Fibers with the product brands Oerlikon Barmag and Oerlikon Neumag is a world leader for filament spinning systems used for manufacturing manmade fibres, texturing machines, BCF systems, staple fibre spinning systems and artificial turf systems and – as an engineering services provider – offers solutions along the entire textile value added chain.

As a future oriented company, the Oerlikon Group segment’s research and development is driven by energy-efficiency and sustainable technologies. With the expansion of the product range to include polycondensation systems and their key components, the company now caters to the entire process – from the monomer all the way through to the textured yarn.

The primary Oerlikon Barmag markets are in Asia, with Oerlikon Neumag’s main markets in the US, Turkey and China. Correspondingly, the companies – with almost 2 500 employees – have a worldwide presence in 120 countries as part of the Oerlikon Manmade Fibers network of production, sales and distribution and service organizations.

At its R&D centres in Remscheid, Neumünster and Chemnitz, highly qualified engineers and technicians develop innovative and technologically leading products for tomorrow’s world.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more