DSM names new head of sales and marketing

Fibre ropes are said to offer a lighter and safer alternative to conventional steel wire ropes for forest holders.

18th July 2014

Innovation in Textiles

|

The Netherlands

Despite continuing mechanisation, harvesting timber places high demands on lumberjacks and materials. This also applies to the ropes used in hauling and winching the timber, leading fibre manufacturer Dyneema reports.

In Austria, both the Archbishop office of Vienna and Ernsthof Forstverwaltung are among a growing number of forest owners who rely on fibre as opposed to steel wire ropes for reasons of ergonomics and safety.

For hauling the logs, both forest owners have been using advanced winch ropes made with Dyneema for more than five years.

Dyneema is DSM’s brand name for its tear and splice resistant fibre of high-modulus polyethylene (HMPE). Typical application comprises a tractor with fixed hauling equipment, including a rope winch providing a traction force of up to 10 tons.

The forestry ropes are manufactured by Teufelberger Company and marketed under the STRATOS Winch Pro brand.

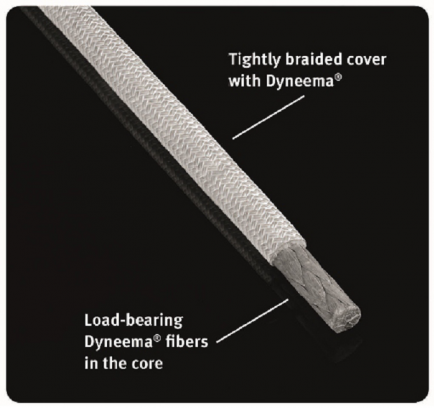

To avoid the core rope that bears the traction force becoming frayed, particularly on rocky terrain, Teufelberger covers the Dyneema core of its STRATOS winch ropes with an especially tight Dyneema braid. With this rope design, even the medium-sized 15 mm diameter STRATOS Winch Pro rope is rated for a minimum break load of 160 kN and a splice resistance of 150 kN, the manufacturer reports.

STRATOS Winch Pro ropes are said to be an extremely rugged, lighter and safer alternative to conventional steel wire ropes. A key argument is their lower weigh, according to Alfred Steiner from the Feistritzwald district management of the Vienna Archbishopric: “It makes a big difference in time and labour, whether two or three lumberjacks must pull a 100 kg steel rope uphill, or whether the same work can be done with a fibre rope that weighs only 12 kg.”

With these fibre ropes, research shows timber can be harvested up to 20% faster, increasing productivity.

Forest engineer Martin Exenberger from Ernsthof Forstverwaltung commented: “Steel ropes, when torn apart, will snap out of control, whereas the synthetic rope will simply fall down without any spiky or broken wire strands. The risk of injury is significantly reduced.”

Erich Rührnößl, Development Engineer at Teufelberger in Wels, Austria, said: “Before introducing STRATOS to the market, we executed comprehensive abrasion, breakage and tensile strength tests in order to make sure the fibre ropes will at least provide the same performance that our customers expect from wire ropes – however at significantly lower weight.“

Teufelberger supports its forestry customers with tailor made accessories, such as special rope end bonds that prevent the winch rope from being pushed off by twitch hooks, thus effectively protecting the rope cover along the entire length of the rope.

Patented splice end bonds permit fast on-site repairs, which is of major importance particularly at low temperatures in winter. For its STRATOS Anchor guyline rope developed for yarders, the company was honoured with Austria’s State Award for Innovation.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more