Nanotube-coated yarns for conductivity

Paid content

Join free webinar and start developing ambitious textile projects.

28th October 2022

Innovation in Textiles

|

Luxembourg

OCSiAl is holding a free webinar on November 29 on the benefits of graphene nanotubes for the creation of multifunctional textiles.

Graphene nanotubes impart functionality to textiles without compromising other important properties such as oil and chemical resistance or flame retardance. They enable permanent, stable electrical conductivity in full compliance with ESD standards to prevent static accumulation and allow use in ATEX, cleanroom, automotive, smart wear and other demanding industries. Ready-to-use solutions based on nanotubes can provide dust-repellent properties, touchscreen compatibility for comfort and save time and laundering costs.

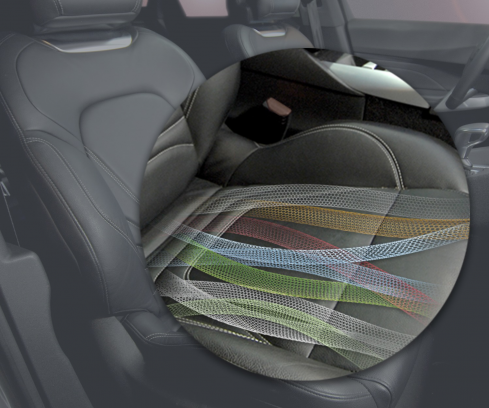

In the webinar, an OCSiAl expert will share examples of textile products empowered with graphene nanotubes. Such market cases include anti-static synthetic leather for hospital bed coverings, ESD-protective wear for workers’ safety, anti-static industrial gloves with touchscreen functionality to increase the automation of industrial facilities, anti-dust synthetic leather car seats for enhanced comfort, electrically heating textile for roof anti-icing, and heating mesh for integration into panels, playgrounds, ladders, and many other applications.

Improved durability, strength, and abrasion resistance of fabric, water repellent features, and flame-retardant properties are also considered as potentially interesting applications for graphene nanotubes and are attracting engineers and technicians to develop highly innovative solutions for transport and medical textiles, smart textiles, yarns, and nonwoven textiles.

Register for the webinar

The webinar is organized by OCSiAl, the global leader in the production of graphene nanotubes and the development of industrial nanotube technologies, leveraged by 1,500 companies around the world, for creating high-performance products. It will take place at 11 am CET on November 29th with a duration of 40 minutes.

Be the first to research more opportunities in functional and smart textiles, whether in nanofinishing or nanofabric and register here.

How and why do graphene nanotubes enhance textiles?

Graphene nanotubes are known as single wall carbon nanotubes. Each graphene nanotube is a sheet of graphene rolled into a tube with a wall the thickness of a single atom of carbon, a diameter of about 1.2–2 nanometers, and a length of around 5 microns.

In contrast to traditional conductive agents, graphene nanotubes have an extremely high aspect ratio – the proportion of length to diameter – which results in unique flexibility and performance. Ultra-low working dosages of graphene nanotubes – hundreds of times less than standard additives – make it possible to create next-gen products with a unique set of properties. So, graphene nanotubes allow textile manufacturers to create completely new materials or market products with a full set of required properties.

About OCSiAl

Headquartered in Luxembourg, OCSiAl is the world’s largest manufacturer of graphene nanotubes. It employs more than 450 people worldwide in locations including the United States, Europe, China, India, Japan, and South Korea. OCSiAl’s nanotubes are the only mass-produced and cost-efficient single wall carbon nanotubes on the market today.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more