Trevira CEO Klaus Holz's contract renewed

At next month’s R+T in Stuttgart, a leading trade fair for roller shutters and sun protection systems, fibre manufacturer Trevira will be presenting its range of polyester fibres and filament yarns for interior sun protection applications. These include flame retardant fibres and yarns, as well as hybrid yarns for the manufacture of stiffened fabrics.

30th January 2012

Innovation in Textiles

|

Hattersheim

At next month’s R+T in Stuttgart, a leading trade fair for roller shutters and sun protection systems, fibre manufacturer Trevira will be presenting its range of polyester fibres and filament yarns for interior sun protection applications. These include flame retardant fibres and yarns, as well as hybrid yarns for the manufacture of stiffened fabrics.

At next month’s R+T in Stuttgart, a leading trade fair for roller shutters and sun protection systems, fibre manufacturer Trevira will be presenting its range of polyester fibres and filament yarns for interior sun protection applications. These include flame retardant fibres and yarns, as well as hybrid yarns for the manufacture of stiffened fabrics.

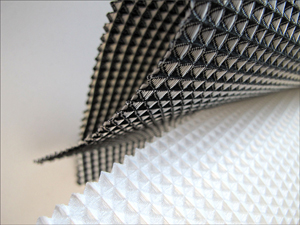

According to Trevira, bicomponent yarns have special properties that make a variety of applications and designs possible and are therefore the ideal ground material for innovative sunscreen textiles. Trevira NSK (niedrig schmelzende Komponente = low melt component) is a modified polyester, from which hybrid yarns can be made in combination with flame retardant yarns. Trevira CS textiles made in this way are used in the contract sector.

The low melt component causes the material to stiffen, with the NSK proportion determining the degree of stiffness achieved. During the finishing process this component makes the textile fabric stiffer. It is not only possible to dye and print the product; it can also be pleated or crushed and modified as required according to the desired aim.

Economic and ecological advantages

Economic and ecological advantages“Hybrid yarns offer considerable opportunities in terms of design and technology, and they have a very textile look. In addition, there are important economic and ecological reasons in favour of their use. It is possible to process them in rational and energy-saving ways,” Trevira explains.

“At the processing stage partial plasticization makes it unnecessary to apply a coating (with acrylate for instance). Products made from these yarns, therefore, offer a substitute for coated textiles, one produced from a single material, since recyclable end products in 100 % polyester can be manufactured without difficulty.”

Flame retardant hybrid yarns can be used in sliding panels, roller and vertical blinds, as well as in room dividers and wall coverings. The stiffness gives the material stability, so that it hangs in smooth sections better than conventional products do. Other applications include soundproofing textiles.

Flame retardant hybrid yarns can be used in sliding panels, roller and vertical blinds, as well as in room dividers and wall coverings. The stiffness gives the material stability, so that it hangs in smooth sections better than conventional products do. Other applications include soundproofing textiles.

“Today Trevira fibres and filament yarns with a melt fibre component constitute a firm proportion of end uses,” Trevira says.

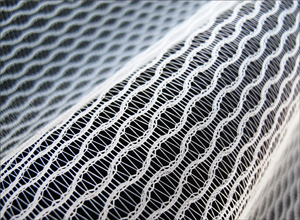

In filaments the yarn range is now supplemented by finer counts, both in finer textured variants and now in flat yarns.

“Flat yarns in particular make it possible to achieve completely new fabrics that have an especially clean impact. It is particularly in the interior sunscreen sector that such very texturless looks are often in demand,” the company explains.

While melt fibre yarns have up until now been used mainly in weaving, the new finer counts have opened up opportunities in the manufacture of stiffened fabrics based on weft or warp knitted materials, offering fresh possibilities in the design of sun protection textiles.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more