The rise of reusables for the UK’s NHS

According to the Hohenstein Institute, the extended usability of innovative protective textiles at hospitals may potentially save about EUR 12.9 million.

10th November 2014

Innovation in Textiles

|

Boennigheim

A current research project sponsored by the German Federation of Industrial Research Associations is working on developing innovative reusable operating theatre textiles, which are more comfortable to wear and at the same time more durable.

With this project, the wfk – Cleaning Technology Institute e.V. and the Hohenstein Institute are complying with the requirements of the Closed Cycle and Waste Management Act (KrWG), also working towards increasing the competitiveness of the German textile industry.

According to the Hohenstein Institute, this research partnership is creating better market opportunities for reusable protective clothing in hospitals. The extended usability of innovative textiles at hospitals may also potentially save about EUR 12.9 million.

The KrWG, as implemented in the Waste Framework Directive RL 2008/98/EC, has been part of German law since 2012.

The reform states that, in order to avoid waste, materials should remain in the production cycle for as long as possible. However, in health care, and especially in hospitals, the trend is in the opposite direction, the Institute reports.

In the interests of ease of handling, guaranteed sterility at all times and cost considerations, the proportion of disposable operating theatre clothing that is used in hospitals is increasing all the time. The resulting waste amounts to about 3.2 kg of textiles per patient per day which have to be disposed of correctly, equating to an annual amount of waste of about 1200 kg for every hospital bed.

Medical textiles, such as bed covers and operating theatre clothing, are classed as licensed medical products and are subject to all kinds of textile technology requirements under the European DIN EN 13795 standard.

These include, for example, mechanical resistance, microbiological purity and a barrier effect against fluids. These standards, designed to ensure the safety of the wearer, mean that the thermo-physiological wearing comfort of operating theatre clothing, and especially of disposable clothing, is a secondary consideration.

To offset the relatively high procurement cost of reusable protective clothing, it must be able to withstand about 50 to 70 cycles of use and reprocessing. Consequently, the wearing comfort of reusable textiles always suffers.

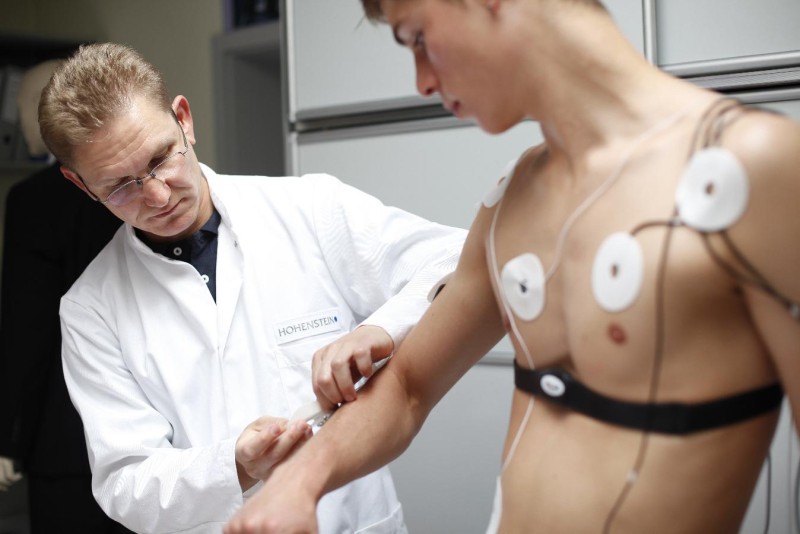

In the light of this problem, this joint research project is developing innovative reusable operating theatre textiles, which are said to offer not only greater comfort but also an extended service life. In the project, the Hohenstein Institute is optimising the materials used for reusable protective textiles to ensure the best possible thermo-physiological wearing characteristics.

The research team led by Dr Bianca-Michaela Wölfling is currently studying the operating theatre clothing that is available on the market with regards to its textile technology and clothing physiology properties.

They are looking especially at the interaction between body, climate and clothing, since an imbalance between the production and the transport of body heat not only makes the surgeon and operating theatre team feel less comfortable as they work, but can also impair their alertness and performance.

The wfk is researching cleaning processes, which would minimise the thermal and mechanical wear on the protective textiles in order to extend their working life.

To make sure that their work is also resource-efficient, the researchers are focusing on pre-activated disinfectant systems and enzymes, which are particularly active even at low temperatures.

The reduction in the washing temperature and the mechanical stresses, together with specially developed cleaning and disinfecting routines, has resulted in an innovative cleaning process, which is said to enable the protective and thermo-physiological textile functions to be preserved better than under the current method.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more