Focus on neelepunch and airlay technologies

International technology group Andritz which offers a full range of complete nonwovens lines for the production of technical textiles will be presenting its expertise in complete lines and advanced systems for high-end technical nonwovens at the India ITME exhibition which runs from 2-7 December in Mumbai. The group’s Küsters, Asselin-Thibeau, and Perfojet businesses will be showcasing integrated solutions for all nonwovens segments for the Indian market.

12th October 2012

Innovation in Textiles

|

Graz

International technology group Andritz which offers a full range of complete nonwovens lines for the production of technical textiles will be presenting its expertise in complete lines and advanced systems for high-end technical nonwovens at the India ITME exhibition which runs from 2-7 December in Mumbai. The group’s Küsters, Asselin-Thibeau, and Perfojet businesses will be showcasing integrated solutions for all nonwovens segments for the Indian market.

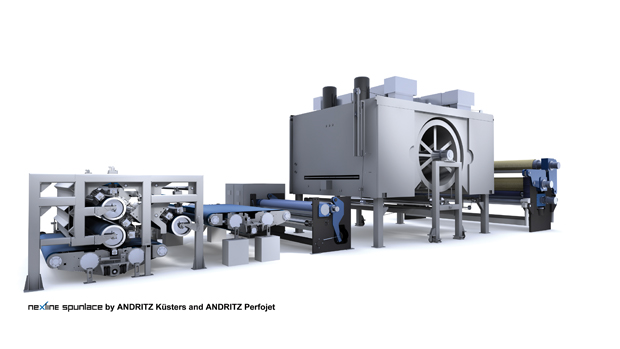

In the spunlace sector, Andritz is a leading machine manufacturer and system supplier which offers high-speed integrated production lines with what it calls unequalled energy efficiency ratio. neXline spunlace, which includes the Excelle carding system, the Jetlace hydro entanglement process, the neXaqua dewatering unit, the Perfodry through-air dryer, and the neXcal twin embossing calender, is said to provide major competitive advantages to spunlace producers.

“The optimum solution for top-speed spunlace lines for commodity products is a combination of Excelle card and Jetlace Essentiel, producing lightweight spunlace at very high capacity and low MD/CD ratio,” Andritz says.

“For new, developing markets, the combination of the Axcess carding machine and the Jetlace Advantage hydro entanglement process is a proven concept, designed to produce lightweight fabrics at low operating costs.”

With the Jetlace machine design, Andritz Perfojet aims to meet the demanding requirements of technical nonwovens producers. The Jetlace Evolution is perfectly designed for the production of durables, such as automotive and filtration substrates. It is equipped with a pre-wetting conveyor in order to control web compacting, maintain the nonwovens quality, and save energy.

Andritz offers a full range of patterning and aperturing solutions by using calenders or sleeves. Andritz Perfojet recently introduced a new 3D patterning technology called neXimaging, an innovative approach which is said to allow any kind of patterning and/or aperture at very high production speed. The sleeve has been designed to reproduce logos and artwork in 3D design with exceptionally high quality detail.

With the ACS system, Andritz Asselin-Thibeau is introducing its latest innovation in crosslapping technology, capable of handling bulky card webs when feeding a cross-lapper. At India ITME 2012, the focus will also be on the benefits of using the ProDyn technology, a feature which aims to guarantee uniformity of the web. Combined with the A50 needle loom series, this solution is said to provide a clear competitive edge for end users.

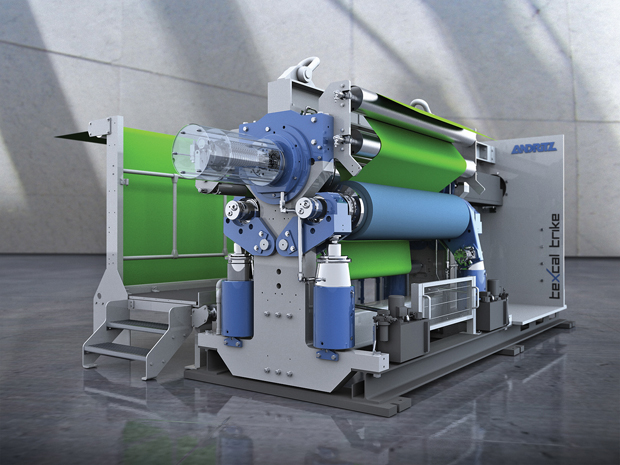

Andritz Küsters has developed a new calender design especially for the production of delicate, technical textiles with very high density. The teXcal trike is a 3-roll calender with S-Roll, Xpro Roll and heated steel roll in a triangular roll arrangement.

The configuration aims to allow extremely flexible production by using one or two nips. Both nips are individually adjustable without influencing the other nip's deflection characteristics. In comparison to standard 3-roll calenders with vertical roll arrangement, the teXcal trike is said to reduce seam loss to a minimum. With regard to the continuously increasing process requirements in the production of technical textiles, the proven deflection control of the S-Roll is combined with additional zone control in the Xpro Roll.

Fields of application include sailcloth, woven monofilament/multifilament fabrics, filters, and parachute silk. In order to optimize material properties, the teXcal trike achieves absolute flatness, air permeability, and defined thickness profiles.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more