Stratasys unveils new advanced materials for 3D printing

Manufacturer of industrial textiles and rolls used primarily in the paper production process, Xerium Technologies has  announced full global availability of its Impact TS, advanced tissue felt technology, as part of its clothing (PMC) technology designed to help customers improve operational performance and reduce energy consumption, which it says are vital to the manufacturing of tissue grades. "With Impact TS, Xerium continues to take the lead in advancing the t

8th November 2011

Innovation in Textiles

|

Raleigh, NC

Manufacturer of industrial textiles and rolls used primarily in the paper production process, Xerium Technologies has announced full global availability of its Impact TS, advanced tissue felt technology, as part of its clothing (PMC) technology designed to help customers improve operational performance and reduce energy consumption, which it says are vital to the manufacturing of tissue grades.

"With Impact TS, Xerium continues to take the lead in advancing the technology of PMC, which is critical to tissue machines' overall energy efficiency and product quality as it is produced," Xerium said in a statement today.

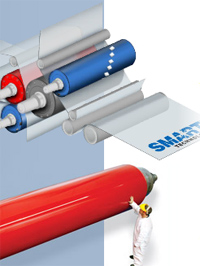

PMC products are highly engineered synthetic textile belts that are used to transport raw paper along the length of the paper-making process, as it is formed, pressed, and dried, keeping in constant contact with the paper as it is formed.

"Through innovations such as Impact TS, we continue to lead the market with technological solutions that boost efficiency and lower the cost of manufacturing paper," said Stephen R. Light, President, Chief Executive Officer and Chairman.

"Time and again we earn our customers' loyalty by developing products with measurable return on investment."

Impact TS is said to incorporate a unique combination of innovative raw materials, highly compressible base structure elements, topped with the company's premium needling technology to deliver outstanding press performance.

According to Xerium, impact TS technology utilizes hydrophilic base yarns aligned perfectly parallel in order to provide an ideal combination of pressure uniformity, exceptional dimensional stability and immediate nip saturation. These unique features provide immediate start-up, lower energy consumption and optimum steady-state performance, the company says.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more