Swissmem’s woven fabrics of the future

The robust and compact design of the company’s MÃœJET MBJL6 1/1380 is said to be ideally suited for top production performance.

28th October 2014

Innovation in Textiles

|

Frick

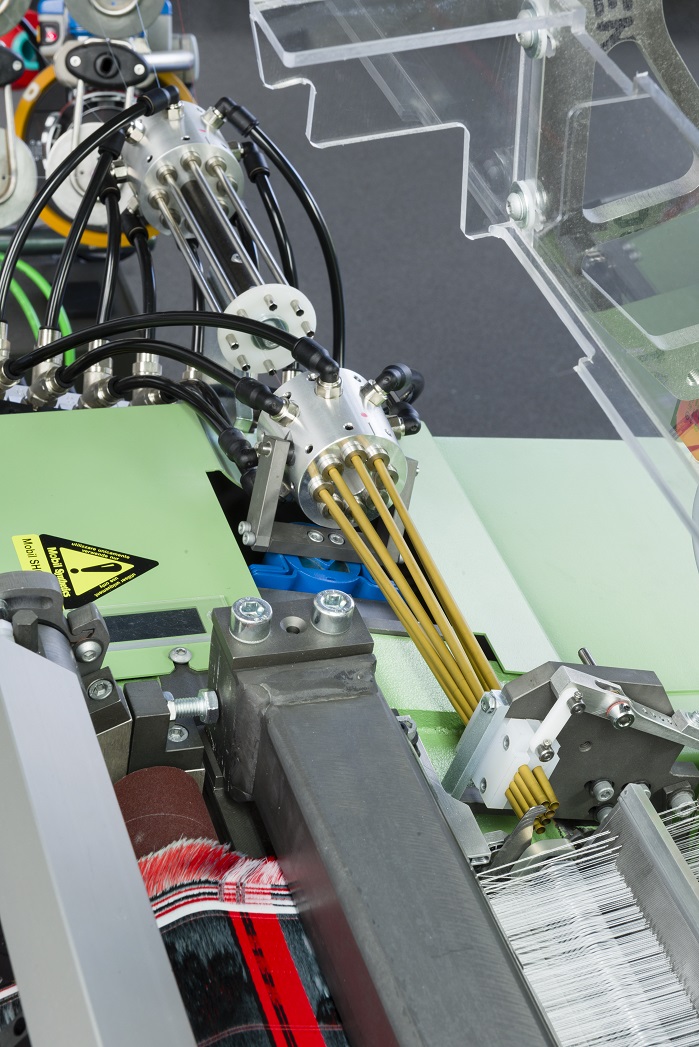

Jakob Müller has introduced its new MÜJET MBJL6 air-jet label weaving machine, the systematic further development of the MBJL machine series, at ITMA Asia + CITME trade fair for textile machinery that took place in Shanghai this summer.

With a speed of 950 min-1 and a working width of 1,200 mm, the MBJL6 facilitates the efficient production of labels, images and technical narrow fabrics with cut selvedges, the company reports.

The robust and compact design of the MÜJET MBJL6 1/1380 is said to be ideally suited for top production performance. It is designed to allow easy access to all the important machine components and control elements.

In comparison with its predecessor model, the working width of the MÜJET MBJL6 has been increased to 1,200 mm. A significantly higher production capacity has also been achieved thanks to a reed width of 1,380 mm and a speed of 950 min-1.

Shedding takes place using an electronically controlled SPE3 1536 jacquard machine with patented bottom shed read-in. The jacquard machine is mounted directly on top of the basic machine, reducing the space required to a minimum.

Additional advantages include a machine height of 3.65 m and its low weight. The new air-jet weaving machine can manufacture more labels per hour in a production area of only 2.05 m by 4.25 m and a reduced building volume.

The careful handling of the warp and weft material during production allows for top speeds and optimum efficiency, the company reports.

The MBJL6 is outfitted with MÜCAN controls and various production conditions can be easily entered using a MÜDATA C-series touch screen. The machine speed can also be quickly and easily adjusted for every pick with the VARISPEED system.

The warp is provided on a warp beam with a maximum diameter of 800 mm. A controlled warp let-off system with a servomotor is said to ensure quick and simple setting of warp thread tension.

Weft insertion on the MÜJET MBJL6 takes place using standard main, acceleration and relay nozzles. The main nozzle is designed for the insertion of eight weft threads.

The number of weft threads per centimetre can be quickly and easily adjusted via a torque motor using the VARIPICK system. This electronically controlled fabric take-off allows the number of weft threads within a repeat to be varied between 18 picks per cm and 120 picks per cm.

The MÜJET MBJL6 can process a wide selection of weft materials such as textured PES, untwisted, reinforced Lurex from 30 dtex to 250 dtex and other fancy yarns.

Labels with sharp edges are caused by temperature fluctuations in the cutting elements and often irritate the skin of the wearer. As such, they are frequently removed from the clothing. The MÜJET MBJL6 is fitted with the TC2 cutting system.

This is said to ensure the uniform cut quality with up to 120 cutting elements. A second cutting beam can also be employed when narrow labels with widths of 6 mm to 8 mm are to be manufactured. A further option is provided by the cableless TVT2 cutting system, which enables the creation of even softer cut edges.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more