Klopman enters South African market

The challenge for the company was to develop a sustainable product capable to maintain fabric standards in terms of comfort and durability.

11th February 2016

Innovation in Textiles

|

Frosinone

Klopman International, the leading fabric manufacturer, has developed a new range of products made with recycled polyester, Fairtrade cotton and/or organic cotton, aiming to encourage new garment manufacturers towards a sustainable business model.

The Europe's leading brand in workwear has been involved in the production and marketing of blended fabrics in 65% polyester and 35% cotton since 1968. Today, the basic yarn utilized for the making up of workwear garments can be replaced by similar materials aimed to reduce the environmental footprint, conservation of resources and to support developing countries, the company reports.

Recycled polyester is made from PET plastic bottles: a resource that would otherwise end up in the waste landfills. The challenge for the company was to develop a sustainable product capable to maintain the features and the fabric standards in terms of comfort and durability.

“A conscious choice can also be done in the selection of the type of cotton to use for the fabric with two options to be taken individually or combined with each other,” says the company.

There are options of selecting an organic cotton, grown using methods and products that have a low impact on the environment (organic soil fertilizers instead of chemical ones, elimination of pesticides, etc.) or Fairtrade cotton, an international organization based on fair trading relationships, committed to a sustainable livelihood for cotton producers and giving support to the local communities.

The company also constantly applies its commitment to innovation in accordance with ethical and environmental considerations in its every-day activities.

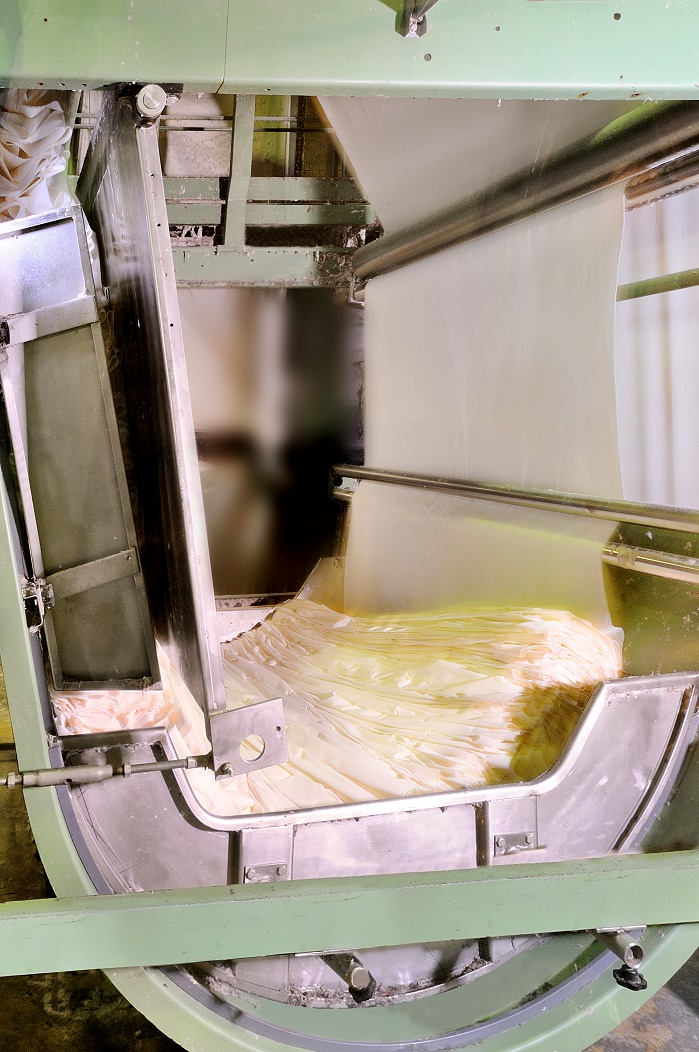

From the selection of raw materials through weaving, dyeing and finishing, the company's engineers are constantly working to minimize the use of toxic substances, reduce waste, reduce energy consumption and to sustain the development of renewable energies.

Klopman produces 70% of its total electricity needs (4 MW) through cogeneration, using steam in the production process that would otherwise be wasted.

The company also contributes towards waste water reduction. The liquid products used in the manufacturing process are neutralised through a double step purification process before discharge. The water, where possible, is recycled to reduce wastage.

The company is also equipped with advanced air extraction systems, which installed throughout the factory, filter and purify the air by minimizing the impact of harmful substances into the outside environment.

Finally, Klopman is compatible with the Directive 2003/87/EC that sets limits for gas emissions to reduce greenhouse effect for EU companies. The CO2 emission limit set for Klopman is about 43,833 tons/year and the emissions produced during 2015 were less than 32,780 tons/year.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more