SGL Group to launch new fibre placement centre

FibeRio Technology Corporation has announced it is to launch the first ever nanofibre production equipment utilizing Forcespinning Technology at the Filtration 2010 and Materials Research Society conferences in Philadelphia and Boston, respectively, from November 30 - December 2. The Cyclone L 1000 series produces nanofibres with average diameters of 500nm and below and it features solution and melt spinning capabilities. Forcespinning is an award winning technol

4th November 2010

Innovation in Textiles

|

McAllen, TX

FibeRio Technology Corporation has announced it is to launch the first ever nanofibre production equipment utilizing Forcespinning Technology at the Filtration 2010 and Materials Research Society conferences in Philadelphia and Boston, respectively, from November 30 - December 2.

FibeRio Technology Corporation has announced it is to launch the first ever nanofibre production equipment utilizing Forcespinning Technology at the Filtration 2010 and Materials Research Society conferences in Philadelphia and Boston, respectively, from November 30 - December 2.

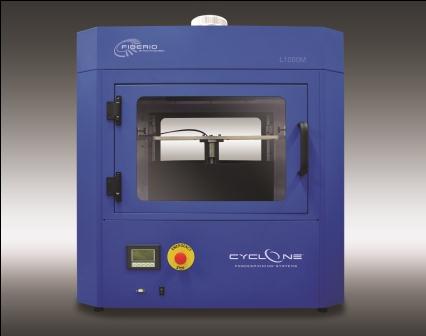

The Cyclone L 1000 series produces nanofibres with average diameters of 500nm and below and it features solution and melt spinning capabilities.

Forcespinning is an award winning technology that utilizes centrifugal force to spin nanofibres, nanowires, and nanorods. In 2010, Forcespinning received the Silver Award at the World’s Best Technology Showcase and was recognized by the Society of Manufacturing Engineers as a ‘2010 Innovation That Could Change the Way You Manufacture.’

“As an equipment company, FibeRio is proud to deliver Forcespinning to advanced materials researchers and the nonwovens and filtration industries,” said CEO Ellery Buchanan. He went on to say that “The Cyclone L-1000 Series is the most versatile nanofibre system ever developed and is the introductory tool for companies anticipating the use of Forcespinning at the industrial scale.”

The Cyclone L-1000 is designed for the laboratory to enable research and development. With 20,000 rpm, melt temperatures up to 450° and multiple spinneret and orifice sizes to choose from, the full range of Forcespinning Technology can be explored, FibeRio. According to the company, there is no dielectric requirement, such as in electrospinning, so organic polymers; inorganic polymers, metals and conductive polymers can all be processed.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more