Promoting good sleep with Outlast

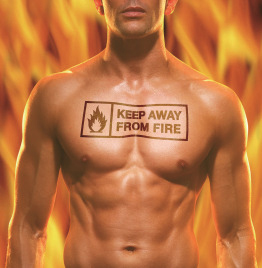

US based Outlast Technologies Inc., market leader in temperature regulating phase change materials (PCMs), and Waxman Fibres Ltd of West Yorkshire, UK, have developed a range of innovative flame retardant (FR) circular knitted fabrics where FR Protex modacrylic fibre is blended with Outlast viscose fibre, to bring new levels of comfort to FR workwear. The new FR fabrics, which will be exhibited at the forthcoming Techtextil in Frankfurt in June, have been produced by

28th March 2011

Innovation in Textiles

|

Heidenheim

US based Outlast Technologies Inc., market leader in temperature regulating phase change materials (PCMs), and Waxman Fibres Ltd of West Yorkshire, UK, have developed a range of innovative flame retardant (FR) circular knitted fabrics where FR Protex modacrylic fibre is blended with Outlast viscose fibre, to bring new levels of comfort to FR workwear.

The new FR fabrics, which will be exhibited at the forthcoming Techtextil in Frankfurt in June, have been produced by the well known innovative Portuguese circular knitter A. Sampaio & Filhos – Texteis S.A., of Santa Tirso, and are made from 60% MAC Protex and 40% CV Outlast. The fabrics are Oeko-Tex Standard 100 compliant and certified by the European norm EN ISO 14116 Index 3, which specifies the performance requirements for the limited flame spread properties of materials, material assemblies and protective clothing in order to reduce the possibility of the clothing burning and thereby itself constituting a hazard.

Outlast claims that because the Protex fibre is blended with the Outlast fibre the new fabrics can provide a uniquely higher level of comfort, temperature regulation and moisture management not normally associated with protective clothing. “We are proud to present another smart development for the workwear marketplace“, says Martin Bentz, Managing Director of Outlast Europe GmbH, based in Heidenheim, Germany. “Protex and Outlast are both well-known brands offering a high added value and also a very good service and technical support to customers.”

Outlast technology was originally developed for NASA to protect astronauts from temperature fluctuations in space. Its phase-change materials (PCMs) absorb, store and release excess body heat and its advantages are said to be that it absorbs excess body heat, manages moisture, reduces overheating, reduces chilling, reduces perspiration and continuously adapts to thermal changes.

Ignition needs flame, flame needs oxygen, fire needs fuel – remove any of these and burning cannot continue. Protex fibres, working with cellulosic partners in the blend, quickly and effectively remove the oxygen from the surface of the fabric, thus stopping the flame from spreading. It does this by producing minute amounts of inert non-combustible gases which ‘seal’ the fabric surface from oxygen. After the removal of the flame source, flame spread is stopped.

“We are very excited to introduce our joint Outlast/Protex product to the market”, says Greg Cluskey, Managing Director of Waxman Fibres. “Protex is permanently and inherently FR, safer than chemical treatments and without loss of FR performance after repeated laundering or dry-cleaning. We are happy to marry our FR fibre to the climate regulating Outlast fibre which also has no loss of the heat management performance after washing.”

“We wanted to take the advantages of our FR technology with the functionality of the Outlast fibre to reduce stress fatigue for the wearer which is what our research has repeatedly requested for the next generation of combined protection. In a warm environment an Outlast/Protex garment keeps the skin temperature cooler and significantly reduces overheating,” added Mr Cluskey.

Both Outlast Technologies and Waxman Fibres will be presenting the new innovation at Techtextil from 24 to 26 May, 2011, in Frankfurt.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more