Scott Bader establishes new business in Japan

These include Scott Bader's carbon fibre compatible Crestapol 1250LV acrylic laminating resin and Crestabond M1-20 primer-less structural adhesive.

13th October 2015

Innovation in Textiles

|

Wellingborough

The ARION1 Land Speed bicycle, designed and built by The University of Liverpool Velocipede (ULV) Team, features high performance lightweight composite materials and technologies. These include Scott Bader's carbon fibre compatible Crestapol 1250LV acrylic laminating resin for the outer shell and the carbon fibre composite (CFRP) chassis frame, and Crestabond M1-20 primer-less structural adhesive to bond a variety of CFRP and metal parts used internally.

The bicycle has recently competed in the IHPVA World Human Power Speed Challenge, an annual speed trial event, which took place from the 14-19 September 2015.

The 2015 attempt by the UVL Team made UK record breaking history, with Ken Buckley setting a new human powered British land speed UK record of 75.03 mph piloting ARION1. Work on ARION2 is already underway by third year engineering students, for a ULV Team to compete again in 2016.

The ULV Team is made up of sixteen undergraduate engineering students, all currently studying for their Masters of Mechanical Engineering (MEng) at the university.

The team, which is the first UK university student team to enter the IHPVA event, designed and built the ARION1 two-wheeled velocipede to compete in the main human powered speed challenge "200 metre flying start single rider" category.

The design, engineering and materials selected for ARION1 focused on maximising the aerodynamic performance and minimising the overall weight of the vehicle, the company reports. Structurally, it needs to handle the high force through the pedals driving the front wheel, support a single rider in a recumbent position and be stable in a straight line at speeds of over 80 mph. Its overall dimensions are approximately 2.8 metres long by 0.85 metres high and 0.5 metre wide. The rider or 'pilot' of the ARION1 velocipede sits almost flat with legs forward, completely enclosed inside a two part carbon fibre composite body shell; the top half is removable to enable rider access.

Carbon fibre reinforcements, foam core materials and related design and processing technical support were provided by key sponsors of the student project including: Far-UK, Evonik, the UK National Composites Centre (NCC), as well as Scott Bader.

According to Scott Bader, the use of carbon fibre with Crestapol high performance resin inside and out of the ARION1 was extensive to achieve the strength to weight ratio needed for this type of speed challenge vehicle.

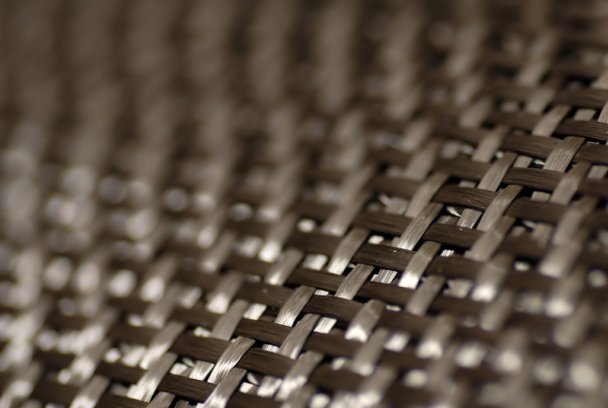

The aerodynamic, rigid, thin walled, outer body shell is a sandwich laminate construction, moulded using carbon fibre fabric, Crestapol 1250LV infusion resin and cut-to-size sections of ROHACELL IG rigid closed-cell PMI foam core. The entire internal frame and where possible other components, such as the seat, the front end section and push rods, were also CFRP fabricated parts.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more