New composites test lab to open in Shanghai

Textile machinery manufacturer Oerlikon Neumag will be presenting its diverse range of products and services at the Domotex Asia / Chinafloor exhibition, which takes place from 26-28 March 2013. The Neumünster based company says that although China has the greatest manmade fibre capacities in the world, the country is considered to be a small BCF (bulk continuous filament) market with development potential based on its consumer habits, for the domestic market as well as for the budding export market.

26th February 2013

Innovation in Textiles

|

Shanghai

Textile machinery manufacturer Oerlikon Neumag will be presenting its diverse range of products and services at the Domotex Asia / Chinafloor exhibition, which takes place from 26-28 March 2013. The Neumünster based company says that although China has the greatest manmade fibre capacities in the world, the country is considered to be a small BCF (bulk continuous filament) market with development potential based on its consumer habits, for the domestic market as well as for the budding export market.

For Oerlikon Neumag, demand in China is primarily focused on BCF yarns for the contract sector and in this area, PA 6 yarns are commonly used due to their higher resiliency. “However, tufted flooring is also used broadly and extensively in the automotive industry,” comments Rainer Straub, Head Product Manager at Oerlikon Manmade Fibers.

“I believe that this sector harbours high growth rates within the Chinese market,” anticipates the expert for flooring applications.

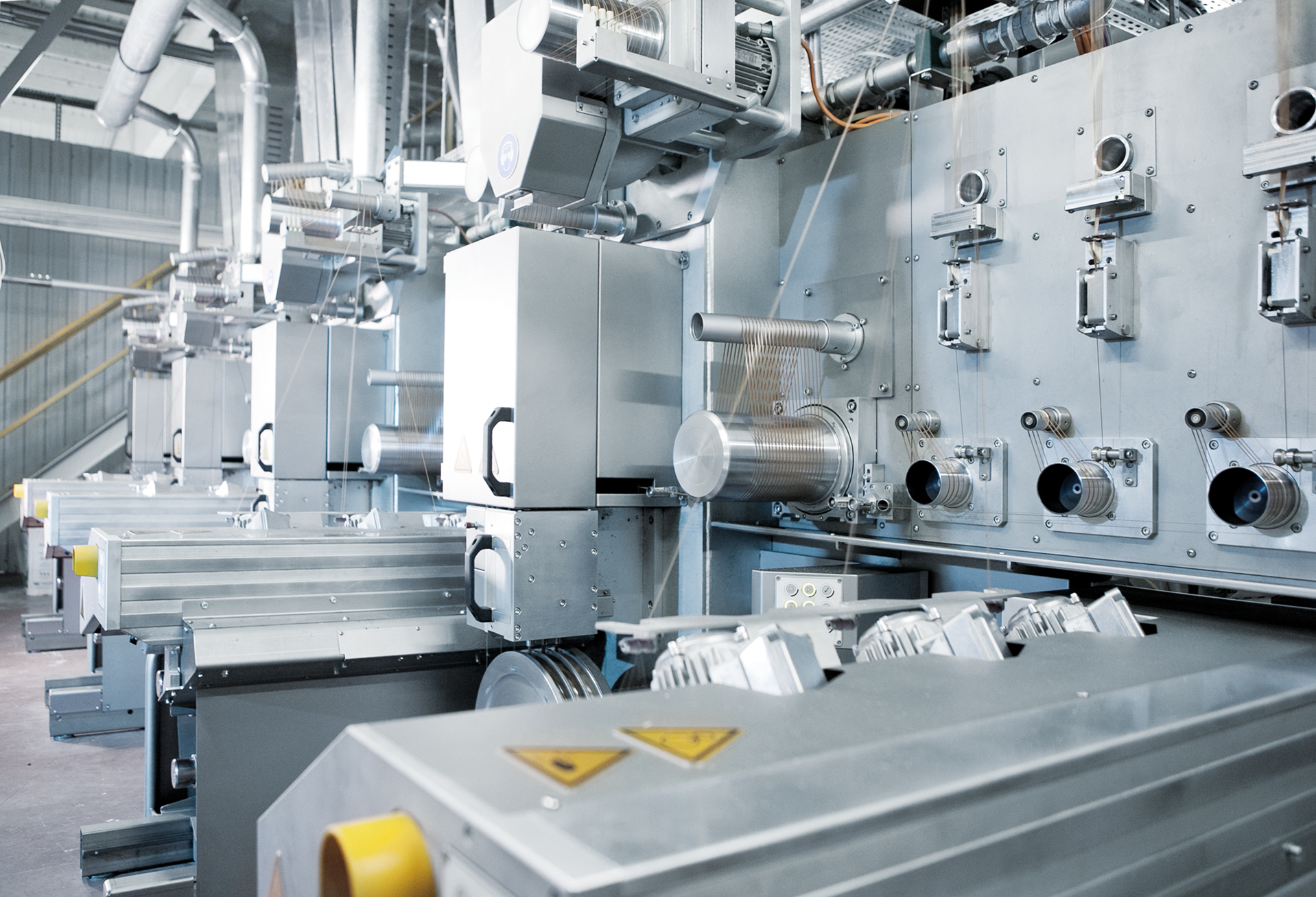

The manmade fibre specialists of the Oerlikon Group offer diverse system solutions for quality-oriented carpet manufacturers. According to the company, innovative products, such as the three-end BCF system S+, not only help yarn producers achieve a technological advantage and increase productivity - 99% efficiency additionally promises low waste rates.

The first S+ in China is scheduled to be put into operation in the spring of this year. With this move, carpet manufacturer Zhengzhou Yifa is now focusing on the production of high-end quality yarns with energy-efficient system solutions. The vertically-integrated carpet manufacturer secures itself a considerable competitive edge within the polypropylene market with the cost benefits generated by the S+.

The S+ three-end BCF yarn system combines the benefits of the S5 and the Sytec One in a fast, efficient and user-friendly machine with tried-and-tested components.

“The S+ has also been available for processing polyester since last year, an important innovation in view of the fact that polyester is globally becoming increasingly significant in the BCF process vis-à-vis polypropylene and polyamide,” Oerlikon Neumag explains.

“The cost benefit is particularly noticeable when substituting polyester spun yarn. With a market share in excess of 70% in the BCF system construction segment, Oerlikon Neumag was able to further expand its already strong market position above all in the main markets of Turkey and the USA.”

The company says that merging with its affiliated brand Oerlikon Barmag, has revealed important synergies particularly in the flooring segment: tapes and monofilament systems manufactured by the Chemnitz-based Oerlikon Barmag subsidiary, are the logical addition to the production of primary and secondary carpet backing.

“A dense service network, particularly within the Chinese market, make the textile segment of the Oerlikon Group an extremely reliable partner for all matters relating to carpet manufacturing,” Oerlikon Neumag concludes.

Oerlikon Barmag is a world market leader for BCF systems and is an established brand within the staple fibre spinning systems and non-woven manufacturing systems sector. Comprehensive engineering services round off the company’s portfolio and as a future-oriented company, a major focus of Oerlikon Neumag’s developments is on energy efficiency and sustainable technologies.

The primary markets for Oerlikon Neumag are the USA, Turkey and China. Correspondingly, the brand, with almost 350 employees, has a worldwide presence in 120 countries as part of the Oerlikon Textile network of production, sales and distribution and service organizations. At its R&D Center in Neumünster, highly-qualified engineers and technicians develop innovative and technologically-leading products for tomorrow’s world.

Oerlikon is one of the world’s leading high-tech industrial group specializing in machine and plant engineering. The company is a provider of innovative industrial solutions and cutting-edge technologies for textile machines, drives, vacuum and solar energy systems, thin-film coating and advanced nanotechnology.

A Swiss company with a tradition going back more than 100 years, Oerlikon is a global player with more than 17,000 employees at more than 150 locations in 38 countries and sales of CHF 4.2 billion in 2011. In 2011, the company invested CHF 213 million in R&D, with over 1200 specialists working on future products and services. In most areas, the company ranks either first or second in the respective global markets.

www.neumag.oerlikontextile.com

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more