Karl Mayer acquires AEI technology

Following the recent acquisition of Benninger’s weaving preparation operations, Karl Mayer has quickly set about the task of integration. For many years now, Germany and Switzerland have been at the centre of first-class warp preparation technology, as represented by two companies, Karl Mayer in Obertshausen and Benninger in Uzwil. Karl Mayer was known originally as a leading manufacturer of warp knitting machines, but extended its product portfoli

14th July 2009

Innovation in Textiles

|

Obertshausen and Uzwil

Following the recent acquisition of Benninger’s weaving preparation operations, Karl Mayer has quickly set about the task of integration.

For many years now, Germany and Switzerland have been at the centre of first-class warp preparation technology, as represented by two companies, Karl Mayer in Obertshausen and Benninger in Uzwil.

For many years now, Germany and Switzerland have been at the centre of first-class warp preparation technology, as represented by two companies, Karl Mayer in Obertshausen and Benninger in Uzwil.

Karl Mayer was known originally as a leading manufacturer of warp knitting machines, but extended its product portfolio in 1950, when its Warp Preparation for Knitting Division was set up. The new division impressed the market with its highly efficient, innovative warping machines and it soon became the benchmark for the latest technology with its staff intent on constantly extending their knowledge and expertise.

Karl Mayer’s first warp preparation machine for the weaving sector appeared in 1991, and marked the beginning of a successful history in weaving preparation technology. As the company continued along its successful expansion course, the product portfolio was constantly extended and optimised, the range of services was improved, and the company’s flair for innovation was strengthened. The aim of expanding its operations was to put the company in a position to supply complete, high-speed solutions for every type of yarn used in the weaving industry. The acquisition of appropriate leading companies within the sector helped the company to consolidate its expertise and capacity even further.

Karl Mayer’s latest move to expand its warp preparation activities was the acquisition of Benninger AG’s weaving preparation operations in December 2008. For 150 years, the Swiss company, has been one of the world’s leading textile companies, with subsidiaries and service centres all over the world. It began building weaving preparatory machines between 1870 and 1880, and used all of its expertise and experience to produce high-quality machines carrying the ‘Made by Benninger’ label.

All machinery supplied by this company, from creels through direct beaming and warping machinery, to sizing and indigo dyeing machines, produced warps of exceptionally high quality and enabled first-rate, reproducible production to be carried out at all times, thus guaranteeing maximum efficiency during weaving. This image is further enhanced by the high calibre of the company’s employees and by its production facilities, which are equipped with the latest machinery.

The Karl Mayer logo appeared on the wall of the company in Uzwil in January of this year. By acquiring Benninger’s Warp Preparation Division, Karl Mayer’s aim is to combine its own innovative strengths and high technical standards with the extensive years of experience gathered by this Swiss company with its long-standing traditions.

The contract between Karl Mayer and Benninger was signed on 1st December, and this immediately put in motion all the steps that had to be taken to consolidate the merger. The aim was to combine the product portfolio, the service operations, and sales and spare parts operations so that they are of maximum benefit to the users. The operations of both companies had to continue seamlessly and also create the right type of structures that would be mutually beneficial to both companies.

The first step involved incorporating Benninger’s technologists into Karl Mayer’s worldwide service network. Karl Mayer has expanded its technical support network to maximum effect; it has been operating successfully for many years, and now provides technical support both for Benninger’s warp preparation machines as well as its own, at the same high level of efficiency that the industry has come to expect. Overall responsibility for service operations relating to Karl Mayer’s warp preparation machines will be based in Uzwil.

The company says that customers will not see any changes in the spare parts service. If they need to replace a component, it can be obtained in the usual efficient way from the parent company in Obertshausen or from its subsidiaries or agents.

The agents are now made up of the representatives of both companies. Choosing which were the most suitable representatives was carried very carefully, and took into account a number of aspects, such as customer service, technical expertise and position in the market. Only the most efficient representatives were awarded a contract and customers can now rely on a first-class technical support service, thanks to a close network of dealers with a clearly defined structure.

The agents are now made up of the representatives of both companies. Choosing which were the most suitable representatives was carried very carefully, and took into account a number of aspects, such as customer service, technical expertise and position in the market. Only the most efficient representatives were awarded a contract and customers can now rely on a first-class technical support service, thanks to a close network of dealers with a clearly defined structure.

The sales teams of Karl Mayer and Benninger were also combined and are now responsible for serving the market efficiently and expertly. A new team has been formed under the direction of Karl Mayer’s former Divisional Manager, Friedrich Maletschek. With all their knowledge and expertise, the members of the team are developing and offering user-oriented solutions from the extended product portfolio.

Karl Mayer says that harmonising the future product strategy is now in full swing. Selecting which products and technologies to integrate into the new structure was based on the principle of choosing only the best technology from both companies to cater for the relevant end-uses.

As far as creels are concerned, all of the successful yarn tensioners will continue to be available. These include models from the ranges consisting of compensating yarn tensioners, the new motor-driven Rot-O-Tense yarn tensioner from Karl Mayer, and Benninger’s Isotens, Dynatens, Megatens and Multitens systems. All the unwinding creels for processing monofilaments, tape yarns and technical yarns will also remain in the company’s offer.

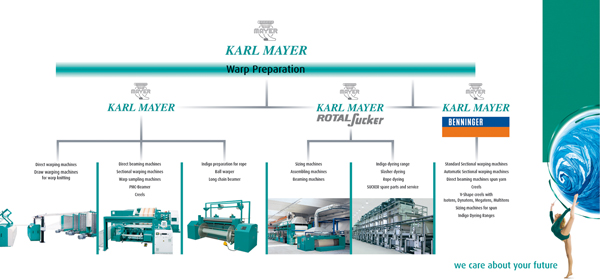

The diagram above shows the range of warping, beaming, assembly beaming, sizing, sample warping and indigo dyeing machines available. Karl Mayer says that the range and quality of this product portfolio can meet all the demands made of a fully integrated supplier who leads the technology and is ahead of its competitors. In order to secure this position, the research and development operations are being combined, a step which is promoting cooperation between the staff of both companies. Karl Mayer’s warp preparation equipment is produced in four countries for the world market, in Germany, China, Italy and now Switzerland.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more