Largest-ever order for Oerlikon Neumag

The company’s RoTac3 is said to make high energy savings possible thanks to its innovative technology.

20th November 2015

Innovation in Textiles

|

Neumünster/Milan

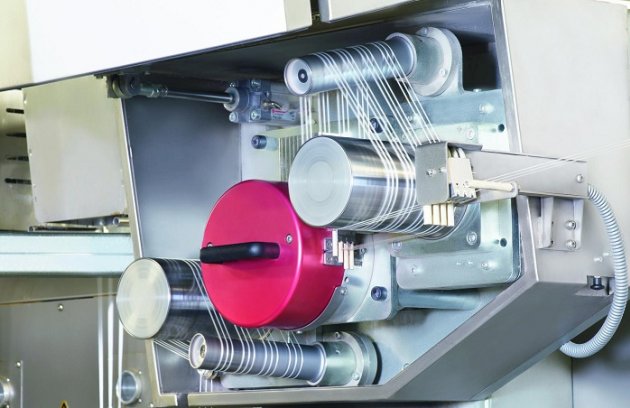

Oerlikon Neumag, a market and technology leader for turnkey plants for the production of BCF carpet yarn, has presented its RoTac3 rotating tangle unit as the company’s highlight at ITMA 2015 that concluded in Milan this week.

According to the manufacturer, its successful launch is a further signal that energy saving and yarn quality are playing a growing role in the production of BCF carpet yarn.

Since the market launch of RoTac3 approximately one year ago, almost 90% of all S+ systems sold for BCF yarn production have been equipped with the new rotating tangle unit, the company reports. “The retrofitting business with the component has also started well,” said Martin Rademacher, Sales Director Oerlikon Neumag. “For us, this is a signal that energy costs in BCF production are becoming ever more important.”

The RoTac3 is said to make high energy savings possible thanks to its innovative technology. In comparison to conventional tangle units, the RoTac3 technology forms the tangle knots with a pulsating instead of a continuous air current. This means that compressed air is only consumed if a tangle knot is to be formed.

This is achieved with a special tangle nozzle that rotates with the yarn. Several holes are incorporated around the nozzle cover, according to the number of desired knots and the distance between them. If a hole is now positioned over the compressed air opening, an air blast is released and tangles the yarn.

Therefore, tangle knots can not only be produced at defined distances and strengths. The discontinuous compressed air impulse also considerably reduces the required volume flow and compressed air consumption – by up to 50% compared to conventional tangle units, depending on the yarn type.

Given increasing process speeds and air pressures to enhance productivity in BCF production, this energy saving is a major advantage, but not the only one, the company reports. The RoTac technology is also designed to eliminate tangle dropouts, which can occur repeatedly at a high process speed with conventional tangling. Last but not least, it ensures very gentle yarn guiding and reduced yarn tension as well as better process stability, according to the manufacturer.

“Many of our customers also confirm that the yarn quality for the downstream processes has improved and the corresponding process steps have been made easier,” commented Martin Rademacher.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more