BMS hardware connects machines to digital Cloud

Sage Automotive Interiors has successfully installed BarcoVision WeaveMaster, KnitMaster and QualiMaster manufacturing execution systems (MES) in its five USA plants. All systems are linked with the company’s Jomar Enterprise Resource Planning (ERP) system. Â When Sage was established in September 2009, a major IT project was set up to select and install a company wide ERP system and replace the legacy monitoring and inspection systems with a standard solut

8th October 2010

Innovation in Textiles

|

Wevelgem

Sage Automotive Interiors has successfully installed BarcoVision WeaveMaster, KnitMaster and QualiMaster manufacturing execution systems (MES) in its five USA plants. All systems are linked with the company’s Jomar Enterprise Resource Planning (ERP) system.

Sage Automotive Interiors has successfully installed BarcoVision WeaveMaster, KnitMaster and QualiMaster manufacturing execution systems (MES) in its five USA plants. All systems are linked with the company’s Jomar Enterprise Resource Planning (ERP) system.

When Sage was established in September 2009, a major IT project was set up to select and install a company wide ERP system and replace the legacy monitoring and inspection systems with a standard solution that could fulfil all Sage requirements. Whilst Jomar was chosen as the ERP solution, selection of the MES (Manufacturing Execution System) system was a demanding task, because of the various applications and interfaces involved.

Ms. Wendy Hammond, Chief Information Officer at Sage, comments: “We were looking for a supplier that could provide us with standard monitoring and planning software for our weaving, knitting and preparation plants as well as a solution for our finished inspection and optimized cutting systems. The extremely powerful optimization algorithms in the BarcoVision QualiMaster system, as well as its possibility to integrate with our automated finished fabric inspection system and its possibility to control the cutting frames, convinced us to go with BarcoVision all the way. A combined Belgium-US development and installation team managed to finalize this prestigious project within the very tight 6 month deadline.”

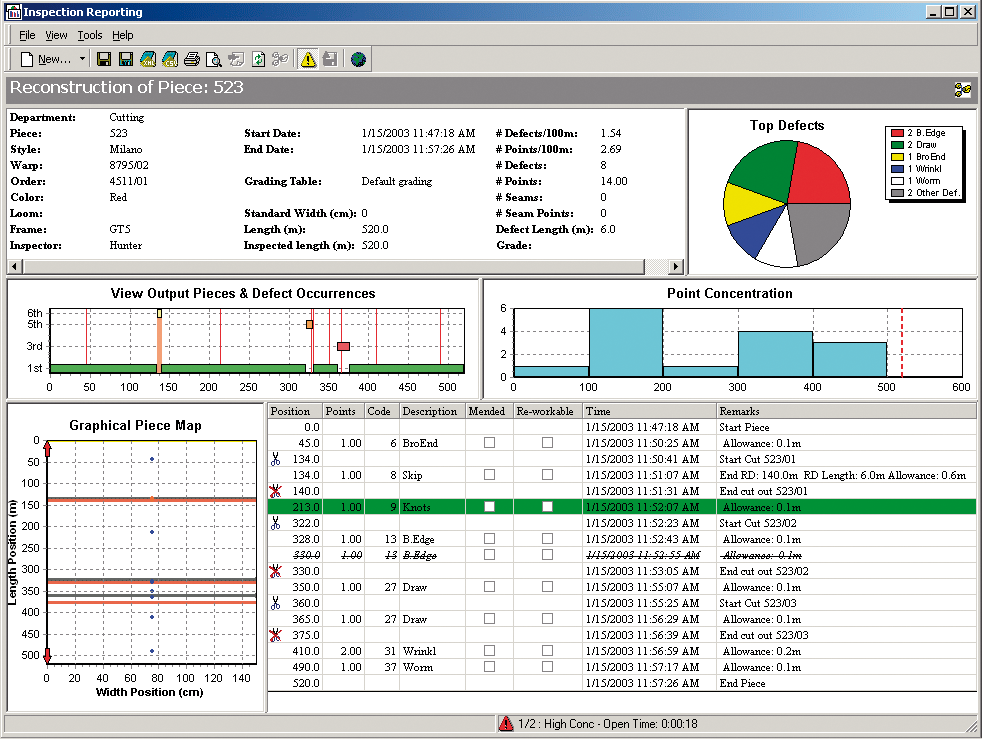

In the finished inspection plants, the piece map resulting from the automatic inspection system is transmitted to the QualiMaster optimized cutting module for optimization based on defect locations and style related grading criteria.

In the finished inspection plants, the piece map resulting from the automatic inspection system is transmitted to the QualiMaster optimized cutting module for optimization based on defect locations and style related grading criteria.

On each cutting frame, a BarcoVision touch screen based industrial PC (GT/FI) is installed. This unit visualizes the cut instructions and controls the speed of the inspection table: when a piece needs to be cut, the speed of the table is automatically reduced.

All systems are seamlessly integrated with the JOMAR ERP system. Style data is transferred from the ERP system into the WeaveMaster and QualiMaster data base and piece information is transferred from the BarcoVision systems to JOMAR for cost accounting and inventory updates.

BarcoVision says it is very pleased to have been selected as the Sage MES partner in these prestigious projects as it further strengthens its position in the US textile market and proves its capability of dealing with the very stringent requirements typical within the automotive supply business.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more