Focus on process technologies at Composites Europe

For the first time, the company will present an isotropic nonwoven prepreg (ICV prepreg) based on recycled carbon fibres combined with an epoxy resin.

16th September 2015

Innovation in Textiles

|

Wiesbaden

At this year’s Composites Europe, the European industry trade show for composite materials taking place from September 22-24 in Stuttgart, SGL Group will be presenting its innovative material solutions along the entire value chain, from carbon fibres, textile products and prepregs to carbon fibre-reinforced components (CFRPs).

“With the constant development of our portfolio, we can offer our customers tailored and innovative solutions in the fields of fibres and components, resulting in significant benefit to customers thanks to favorable process capability and enhanced properties. We will be demonstrating this with the many product innovations on show at Composites Europe,” commented Andreas Wuellner, Head of Business Unit Carbon Fibres and Composite Materials.

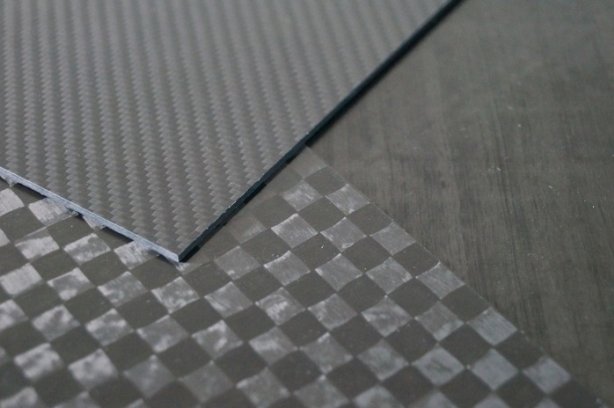

In addition, SGL Group will be showcasing its current development activities. For the first time, the company will present an isotropic nonwoven prepreg (ICV prepreg) based on recycled carbon fibres combined with an epoxy resin.

Due to a new manufacturing process that makes it possible to use recycled carbon fibres, this material possesses almost isotropic mechanical properties, according to the manufacturer.

The ICV prepreg has an entirely new type of surface appearance and can be used in pressing processes as well as conventional autoclave processes. These characteristics make the material especially interesting as a means of opening up new applications with epoxy resin prepregs, the company reports.

The SIGRAPREG prepregs of SGL Group can also be combined with new fast-hardening resin systems that are currently being developed with a view to the requirements of future large-scale component production. These snap-cure resin systems are said to combine great hardening times, good storage stability and adhesiveness of the pre-impregnated semi-finished products optimized for automated machining.

An additional highlight in terms of innovative product solutions will be the presentation of the SIGRAPREG TowPreg, which has already been shown for the first time at JEC 2015. These pre-impregnated rovings made from carbon or glass fibres are especially suitable for challenging winding and lay-up processes thanks to their outstanding winding properties, which results in excellent mechanical properties in the component.

As an innovation in the field of thermoplastic fibre composites, SGL Group will be presenting long fibre-reinforced thermoplastics (LFRPs) for the first time. These materials are available as both glass fibre-reinforced and carbon fibre-reinforced semi-finished products on the basis of various plastic types and enable significant inherent benefits, such as short cycle times, weldability, good recyclability and ease of combination with other thermoplastic semi-finished products.

The new thermoplastic materials and their applications will be presented at the trade show using the example of a front end. This is made from LFRP consisting of glass-fibre-reinforced polyamide (GF-PA6). Unidirectional (UD) tapes and carbon fibre-based organic sheets are integrated directly in a manufacturing process step and thereby reinforce structures of the front end under high local stress.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more