True Temper partners Hexcel on latest high-performance golf shafts

Leading golf club shaft manufacturer True Temper has recently released a new version of its Project X shaft series, the PXv 39 (v for velocity) - aided by the use of TeXtreme Spread Tow carbon fabrics, the PXv weighs just 39 grams and is said to be the lightest shaft introduced to the market.

2nd April 2013

Innovation in Textiles

|

Borås

Leading golf club shaft manufacturer True Temper has recently released a new version of its Project X shaft series, the PXv 39 (v for velocity) - aided by the use of TeXtreme Spread Tow carbon fabrics, the PXv weighs just 39 grams and is said to be the lightest shaft introduced to the market.

“We have combined ultra-high modulus torsional plies with TeXtreme to provide a stable core from which to build the PXv 39. This ultra light, ultra stable core has enabled us to create a sub 40 gram golf shaft that is not only durable but provides the penetrating ball flight that golfers have come to expect from the Project X franchise” says Don Brown, Project X product development manager and designer.

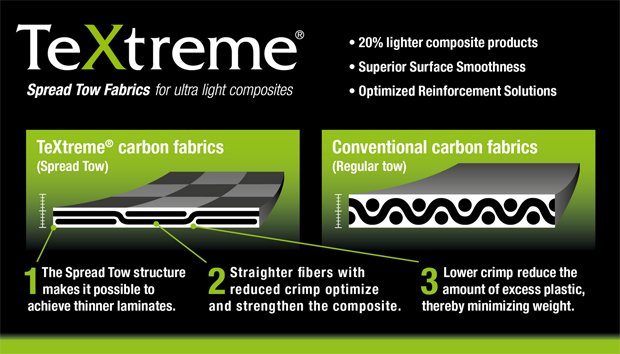

TeXtreme Spread Tow carbon reinforcements are a composite reinforcement suited to applications where the user is looking to reduce weight and improve mechanical properties. It has been successfully used in Formula 1, Americas Cup and Advanced Aerospace applications as well as other sporting good applications such as bicycles, skis and ice hockey sticks.

“TeXtreme is becoming the new standard carbon reinforcement for high-end applications where low weight and performance is key. The unique benefits TeXtreme renders is repeatedly proven by the results and constant victories by our customers. We also take big pride in providing an optimized reinforcement solution for each specific application need and also we make sure the solution is realized into full scale production”, says Henrik Blycker, CEO of Oxeon, owner of the TeXtreme brand.

According to the company, the use of TeXtreme “allows elimination of weight compared to the original design while maintaining the low torque and low spins properties that established Project X as the standard for all high-performance composite shafts.”

TeXtreme Technology is said to be flexible and tow-size independent which enables development of optimized reinforcement solutions tailor-made for specific application needs. “Utilization of TeXtreme Spread Tow carbon fabrics and carbon UD tapes by manufacturers of advanced aerospace, industrial and sports products confirms that 20-30% lighter composite parts can be produced with improved mechanical properties and superior surface smoothness,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more