Tufts sees potential in biological electronics

Allowing a fabric to think and act autonomously.

4th February 2026

Innovation in Textiles

|

Shanghai, China

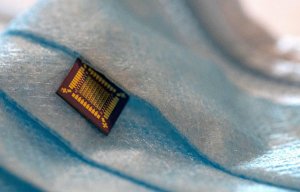

A research team at Fudan University in Shanghai has successfully built complex electronic circuits inside thin, flexible fibres.

These ‘fibre chips’ allow fabrics to process information like a computer while remaining soft enough to be woven and stretched and twisted in everyday clothing.

Typically, computer chips are flat and rigid, built on stiff materials like silicon and because fibres are curved and have very little surface area, it has been difficult to fit enough electronic parts onto them to make them useful. To solve this, the Fudan University team moved away from just using the surface of the fibre. Instead, they designed a multi-layered spiral architecture, essentially building several layers of circuitry inside the fibre to use all the available internal space.

The team’s experiments show that a fibre chip only one millimetre long can hold up to 10,000 transistors – the tiny switches that process data in electronics. This gives it the same processing power as a chip used in a heart pacemaker. If the fibre is extended to a metre, it could hold millions of transistors, reaching the power levels of a standard desktop computer processor.

The research, which challenges the traditional way computer chips are made, was published in the journal Nature.

For decades, scientists have added basic functions to fibres, such as the ability to store energy or sense touch. These smart fabrics, however, usually have to be plugged into bulky, rigid computer chips in order to function. This makes clothing stiff and uncomfortable. The new fibre chip eliminates that need, allowing the fabric to think and act autonomously.

“Our fabrication method is highly compatible with the current tools used in the chip industry,” says Chen Peining, a researcher at Fudan University’s Institute of Fibre Materials and Devices. “We have already achieved a way to mass-produce these fibre chips.”

The technology has significant implications for healthcare. In the BCI (brain computer interface) field, current systems use stiff electrodes that must be wired to external computers. The fibre chip could allow for a closed-loop system where sensing, data processing, and medical stimulation all happen within a single, soft fiber.

Professor Peng Huisheng, a co-author of the study, notes that these fibres are as thin as 50 micrometres and as flexible as brain tissue.

“This makes them safer and more effective in the treatment of neurological diseases,” he observes.

In the world of virtual reality, the technology could also lead to smarter tactile gloves since current VR gloves often use clunky hardware that makes them feel unnatural.

“Smart tactile gloves made with fibre chips are indistinguishable from ordinary fabrics,” says Chen “They can sense and simulate the feel of different objects, which could be used by surgeons to ‘feel’ the hardness of tissue during a remote robotic surgery.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more