Supersonic flight is back with a Boom

Combining the best of both additive and existing carbon composites manufacturing.

23rd February 2022

Innovation in Textiles

|

Zürich, Switzerland

Swiss Supplier of advanced carbon composite manufacturing technology 9T Labs – a spin-off from ETH Zürich – has raised $17 million in Series A Funding.

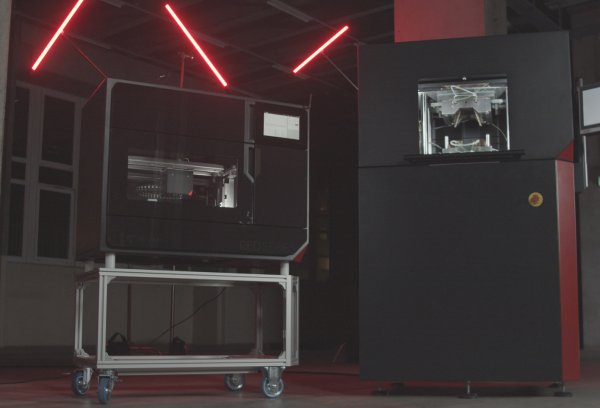

The investment will help fully commercialise the company’s Red Series additive fusion platform for the production of advanced carbon fibre-reinforced thermoplastic (CFRTP) composite parts. Key investors include the world’s leading 3D printing company Stratasys and the venture capital arm of high-performance thermoplastic composites supplier Solvay.

The company’s technology enables desktop size high-performance structural parts to be produced in CFRTP composites in production volumes ranging from 100 to over 100,000 parts/year.

It combines software and 3D printing – offering unexcelled design freedom, part complexity and control of fibre orientation – with compression moulding in matched metal dies providing rapid cycle times, high production rates, excellent surface finishes and low voids. As such, the platform offers the best of both additive and existing manufacturing to create a more sustainable and high-performance alternative to traditional metal and plastic manufacturing technologies.

It is already used by Fortune 500 aerospace companies to lightweight its future mobility programmes, by medical corporations to reduce material waste for manufacturing medical instruments and by the leisure and luxury industry to provide consumer products with increased functionality.

The global 3D printing market is predicted to grow at a compounded annual growth rate (CAGR) of 25% to exceed a value of $100 billion by 2030 in the $2-trillion global parts manufacturing segment.

“9T Labs has combined the simplicity of 3D printing with the strength of continuous carbon fibre composites, and that’s an exciting development for our industry,” said Adam Pawloski, VP of manufacturing solutions at Stratasys. “Its additive fusion technology leverages the benefits of printing, automated tape laying and compression moulding to deliver fully dense parts with multi-directional reinforcement. In addition, the technology scales to the volumes of production parts needed by serial manufacturers. The end result is a solution with the potential to dramatically shift the industry away from metal and towards composite parts.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more