Soaring prospects for aerospace industry

Unlike their metal counterparts, composite structures do not conduct away the electrical currents and electromagnetic forces generated by lightning strikes.

18th March 2021

Innovation in Textiles

|

United Kingdom

US based Kordsa companies Fabric Development Inc. and Textile Products Inc. are providing new lightning strike protection and EMI shielding fabrics to the aerospace industry.

With increased resistance and durability and improved shielding ability, the fibre and wire hybrid fabrics reduce the energy density of lightning flowing onto a composite structure and provide greater impact resistance to improve the life cycle of the part to which they are applied.

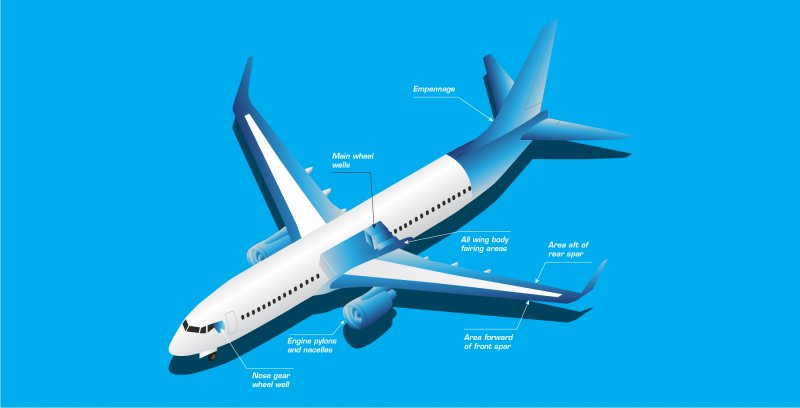

According to statistics, a plane can be struck by lightning once a year on average, making protection highly essential in aircrafts for the safety of various components including generators, fuel valves, electrically controlled power feeders, and electrical distribution systems.

However, unlike their metal counterparts, composite structures do not conduct away the electrical currents and electromagnetic forces generated by lightning strikes. As the use of composites has expanded during the past three decades, a wide range of lightning strike protection fibres has been adopted for aerospace industry.

Kordsa’s two US-based companies already offer such fabrics in a wide range of fibre and construction options as well as those engineered to meet specific customer needs in respect of weight and conductivity.

Lightning Strike Protection and EMI shielding fabrics provide weight advantages compared to alternative approaches and can be produced with multiple fibre systems such as carbon, glass, and aramid along with multiple conductive wires such as copper, aluminium, bronze and nickel. Wires are chosen to meet a required conductivity. The fabrics can be prepregged using standard equipment and is easier to mould in comparison to expanded metal. Ease of cutting and handling during kitting or lay-up are further advantages.

Kordsa acquired both Fabric Development Inc. and Textile Products Inc. in 2018.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more