Aerospace potential for graphene

The A380 contains over 10,000 parts made from continuous fibre-reinforced thermoplastic composites.

17th June 2025

Innovation in Textiles

|

Europe

Toray Advanced Composites, Daher, and Tarmac are launching a new end-of-life aerospace recycling program for commercial aircraft production.

Working with Airbus, the collaborative project aims to extend the useful life of composite materials by developing remanufacturing processes and creating a closed-loop recycling system, initially by reutilising secondary structural thermoplastic parts from end-of-life Airbus A380 aircraft.

Airbus will provide support for the advanced material reuse framework while Tarmac Aerosave will ensure components are dismantled without damage, preserving material integrity. Daher is leading the reshaping and the quality of repurposed parts, while Toray, as a materials supplier, is monitoring the material quality for the second-life application.

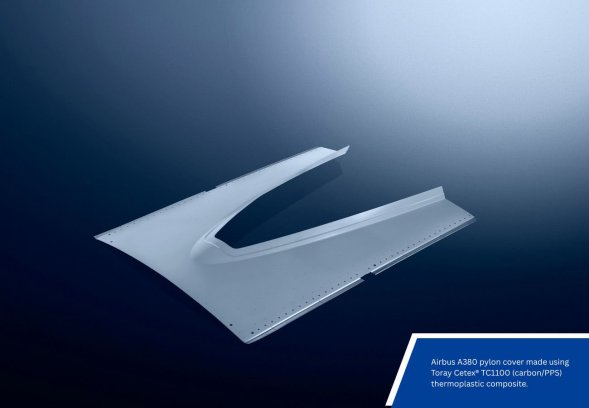

At the core of this initative is the end-of-life recycling of the A380 pylon cover, specifically the Toray Cetex TC1100 (carbon/PPS) thermoplastic composite structure. As thermoplastic parts become more prevalent in next-generation aircraft, this pilot case sets the foundation for new methodologies in recycling, repurposing and reprocessing composite materials. The A380 alone contains over 10,000 parts made from continuous fibre-reinforced thermoplastic composites, making it an ideal platform for testing and validating recycled material recovery practices.

“Thermoplastic materials offer great potential for recycling,” says Scott Unger, CEO of Toray Advanced Composites. “Through this initiative, we aim to explore new opportunities for recycling technology development, where our high-performance materials are not just recycled, but meaningfully reused and reintegrated into other structural aerospace applications.

“As demand for commercial aircraft continues to increase, it is critical we make progress on the recyclability of thermoplastic and thermoset composite materials and reduce the impact of our industry on the environment.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more