Europe’s flax harvest on track

This week sees the completion of seaweed harvesting in Europe’s first trials of seaweed cultivation in the open ocean using advanced textiles, developed specifically for large scale cultivation of seaweed for biomaterials and biofuels in coastal seas. Devised as part of a 3-year European project called AT~SEA, the textiles have been subjected to simultaneous trials in inshore waters off the coasts of Norway, Scotland and Ireland to expose the textiles to different oceanographic, environmental and climatic conditions on a latitudinal gradient.

5th July 2013

Innovation in Textiles

|

Kerrera, Scotland

This week sees the completion of seaweed harvesting in Europe’s first trials of seaweed cultivation in the open ocean using advanced textiles, developed specifically for large scale cultivation of seaweed for biomaterials and biofuels in coastal seas.

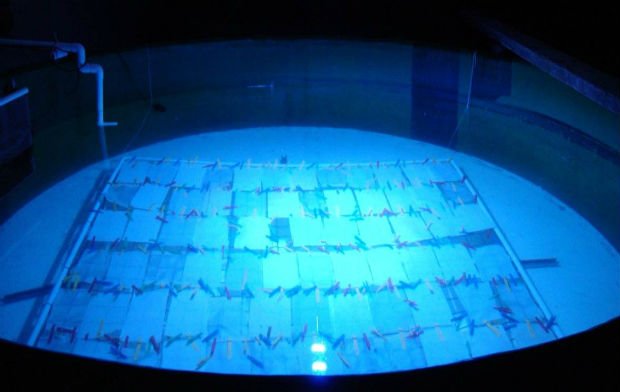

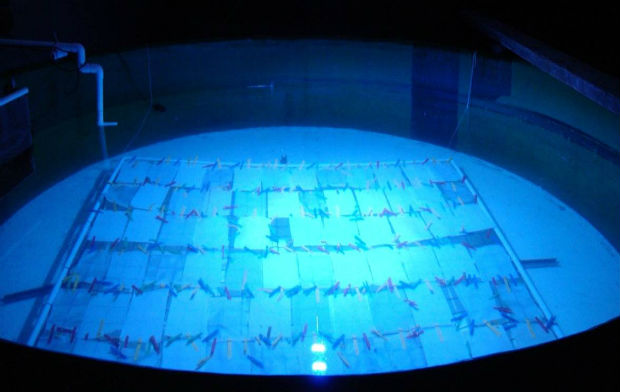

Devised as part of a 3-year European project called AT~SEA, the textiles have been subjected to simultaneous trials in inshore waters off the coasts of Norway, Scotland and Ireland to expose the textiles to different oceanographic, environmental and climatic conditions on a latitudinal gradient.

Following the trials the 11 project partners, which include businesses, industry and research institutes, will assess which textiles offer the optimal performance across Europe. These results will lead to the manufacture of a second generation of specifically designed textiles in time for the start of the next growing season.

.jpg)

Research in to the development of economically and environmentally viable production of biomaterials and biofuels (methane and ethanol) from seaweed has been on-going for some years. It has been established that mass harvesting of wild growing seaweed is not economically viable in Europe and that harvesting of beach cast seaweed is detrimental to coastal ecosystems.

“The AT~SEA project aims to make mass cultivation of seaweeds in Europe’s near-shore locations technically and economically feasible by creating textile substrates that can endure the harsh conditions that they are exposed to as the seaweed grows,” says Bert Groenendaal of Sioen Industries and coordinator of the AT~SEA project.

Seaweed biomass remains a good alternative as a source of non-oil based materials such as biofuels, biopolymers, pigments, anti-oxidants and other chemical compounds that can be derived from seaweed.

The future of terrestrial biomaterial and biofuel crops is in doubt: they take up valuable land for food production and consume large amounts of water. With almost 71% of our planet covered by oceans that are bounded by extensive coastlines, growing biocompounds at sea bypasses the environmental and economic problems associated with their production on land.

The AT~SEA project has brought together European leaders in technical textiles, offshore engineering and marine biology to make the production of marine based chemicals and biofuels viable, feasible and a reality.

The project aims to make mass cultivation in inshore locations feasible by creating growth substrates that can endure the tests of a constantly wet, salty, moving, sometimes raging sea on which to grow the seaweed. The textiles being trialled are a mix of woven, nonwoven and 3D layered fabrics based on advanced fibrous and fibre-composite materials. The textiles may also be coated or modified to encourage the growth of a particular species.

At the moment the project is developing other materials for mooring and positioning the cultivation textiles with possible applications in many marine industries. These advanced textile-based cables and connections will be engineered to be robust, durable and with high tensile strength to survive near shore and offshore conditions.

The third part of the project is to design flexible and lightweight tanks for storing and transporting harvested seaweed, for housing offshore seaweed hatcheries, and for cleaning and maintaining the cultivation textile ropes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more