Miller Weldmaster adds radio frequency welding solutions

A report recently published by The Freedonia Group projects that global demand for geosynthetics will reach 5.2 billion squares in 2017. As geo liner and cover manufacturers gear up for this increased demand, Miller Weldmaster offers a range of solutions for cutting back on production times and costs associated with production time.

12th March 2014

Innovation in Textiles

|

Navarre, OH

A report recently published by The Freedonia Group projects that global demand for geosynthetics will reach 5.2 billion squares in 2017.

As geo liner and cover manufacturers gear up for this increased demand, Miller Weldmaster offers a range of solutions for cutting back on production times and costs associated with production time.

The market research firm predicts that the growth will be tied to improved conditions for road and structure building, as well as growing concerns regarding environmental protection and greater awareness of the performance advantages of these products in a variety of applications.

The company’s geo welders are said to enable geo manufacturers to increase their production output, minimise their labour inputs, and eliminate excessive fabric handling.

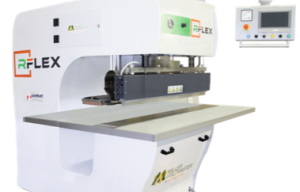

Two machines in the company’s Autobond Automation Series, the Miller Weldmaster Traveling Geo 3600 and Traveling Geo Stationary 3600 are constructed to make fabric welding as seamless and efficient as possible.

Both machines are built to produce almost any size liner or cover while minimising production times. On the whole, Miller Weldmaster has installed over 3,000 machines in over 100 countries across the globe.

Miller Weldmaster, a leader in all industrial fabric welding solutions, has been producing rotary hot air, hot wedge and impulse welding equipment to the industrial fabric and thermoplastics industries for forty years.

For the fabrication and automation of various products from awnings to truck tarpaulins, to inflatable boats, the company has developed many of the first advancements in heat sealing technology.

Having sold machines in over 100 countries and with distributors in 20 countries, Miller Weldmaster Corporation is a leading international manufacturer and provider of solutions for plastic welding machines.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more