Sophisticated solutions for sound

German nonwovens producer Sandler AG has reported a 6th successive year of growth in sales, increasing its sales volumes to Euros 247 million in 2012.

28th February 2013

Innovation in Textiles

|

SChwarzenbach

German nonwovens producer Sandler AG has reported a 6th successive year of growth in sales, increasing its sales volumes to Euros 247 million in 2012.

In a statement issued by its management today, the company says it recorded growth in all market segments, from hygiene and wipes applications, to technical applications for automotive, filtration, construction and technical insulation markets, as well as in nonwovens for home textiles and office acoustics.

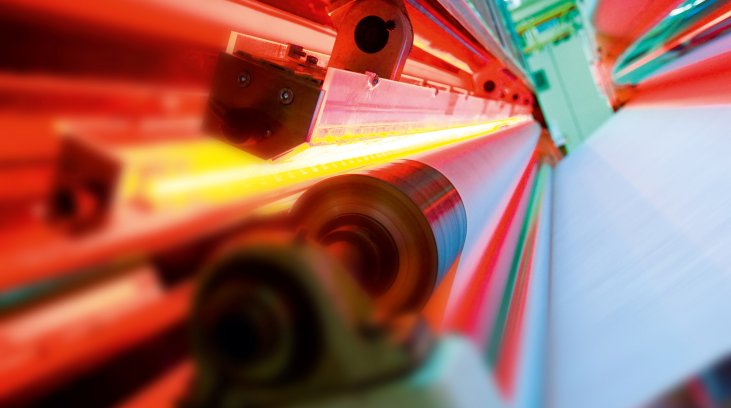

Staff numbers at Sandler rose by 20 in 2012 to a total 570 employees and at its headquarters in Schwarzenbach, the company invested Euros 6.5 million in a new meltblown production line which expands its capacity for manufacturing synthetic filter media - which will continue to be one of the drivers of growth for the company.

According to Sandler, innovation and advancement, flexibility and service are all part of its credo and true to this philosophy it has developed the Schwarzenbach location into a centre of excellence for the production of nonwovens.

“The flexible transfer of know-how between the departments, the deployment of various production technologies in new fields of application and synergy effects resulting from this wide range have become one of Sandler’s signature features,” the company explains.

Sandler realises that the continuous optimisation of production processes is essential to its growth and at the state-of-the-art production facility professional maintenance is a top priority, both in terms of safety considerations and with respect to product quality.

Qualified staff members from the operating technology department ensure that production runs smoothly around the clock and in the case of the company’s largest production lines, the maintenance team consists of up to 50 professionals. Procedures are accurately defined, ensuring quick response in case of disruption and the swift repair of malfunctions.

In 2013, Sandler will invest Euros 2.5 million in expanding its maintenance centre, where a new section of the building will accommodate up to 20,000 replacement parts, which will be kept on hand for its state-of-the-art production lines.

Intra-company logistics will support the reorganisation in order to continue operating efficiently. Meanwhile, Sandler will focus on sustainability and the preservation of valuable resources both in-house and in the transportation of raw materials and finished goods.

Every month, up to 1000 truck and container loads leave the company and are shipped to customers around the globe. “Choosing the right means of transportation makes all the ecological difference. When it comes to the delivery of raw materials Sandler also banks on reducing the carbon footprint and has transferred these movements of goods to rail wherever possible,” the company says.

“This way, Sandler strives to protect the environment and to remain a flexible and reliable partner in international trade. The status Authorized Economic Operator and the certification AEO-F (customs and security) obtained in May 2012 are evidence of Sandler being a reliable partner, whose entire supply and manufacturing chain is considered safe as per EU and German regulations.”

In the wake of the energy transition, efficient heat insulation in buildings is at the centre of attention for both companies and consumers alike and in its sector, Sandler says it is taking a new path:

“Every day we count on textiles to protect us from the weather and other external influences. Why not also rely on these functional comfort-bringers when it comes to conserving energy,” says CEO Dr. Christian Heinrich Sandler. “In various technical applications textiles offer an ideal combination of comfort and functionality.”

“Nonwoven panels reliably insulate heat, even on uneven surfaces, and prevent heat loss through roof and walls – a definite plus when it comes to energy consumption. They are agreeable to the skin and easy-to-handle without having to use any protective equipment. Polyester, the material that protects us in the form of comfortable clothes and makes recycling a daily routine in the form of beverage bottles, is the material of choice for these products,” Sandler explains.

The fabrics are single-polymer and partly made of recycled fibres and at the end of their operating life, they can be reprocessed and put to new use. In 2012, these new developments were at the centre of attention when Sandler’s first participated in the ISO trade fair in Cologne, the leading European trade fair for insulation materials and technology.

Sound insulation, especially in office spaces, was another focal point in Sandler’s product development last year and in this area of application, the company says, “nonwovens also offer a textile alternative, create pleasant conversational acoustics and, at the same time, are a real eye-catcher with respect to product design.”

“Printed or embossed, they create an individual room layout in partition walls or suspended ceilings; for a pleasant ambiance at the workplace,” Sandler adds. Likewise at the Orgatec 2012 trade fair in Cologne, manufacturers of office equipment had the opportunity to have a first-hand look at the new developments.

According to Sandler, the production of these nonwovens is energy-intensive and the preservation of valuable resources and the reduction of the CO2-emissions are, it says, the focus of its energy management, which has been certified according to DIN EN ISO 50001 since 2012.

In this area, Sandler says it again demonstrated its capability for innovation. In addition to the ongoing documenting of its energy consumption and the implementation of measures towards its reduction, the company has installed energy monitors on its production lines.

The system indicates real-time energy consumption, allowing experienced staff to optimise it by means of specific modulations during production, without affecting the quality of the finished product. In 2012, Sandler received a small and medium-sized enterprises award in the Environment/Sustainability category for this particular innovation.

Sandler is optimistic both for 2013 and for the future and concluded: “In 2013 Sandler will again face various challenges – from the economic development, to raw material prices, through to the energy transition. However, in light of the company’s positive development across the years, Sandler’s management optimistically look to the future. Staff members and executives identify with the company and bring it forward with their competence and experience – an ideal basis for the continued growth of one of the world’s largest nonwovens manufacturers.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more