Bringing softness to hemp in denim

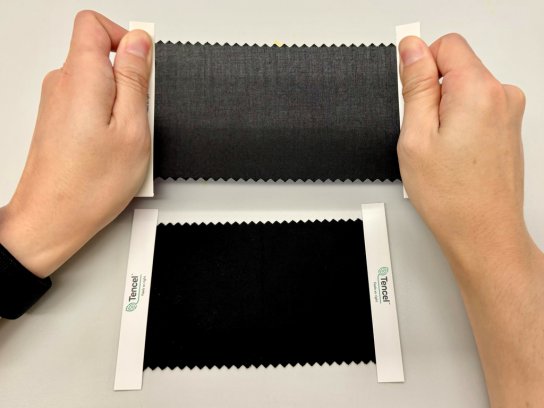

Pre-treatment increases the yarn crimps in the width-wise direction of the fabrics.

19th January 2024

Innovation in Textiles

|

Lenzing, Austria

Lenzing has developed a new method for producing woven fabrics with Tencel lyocell that exhibit exceptional stretch and recovery properties.

It involves a wet fabric pre-treatment during which the fibres undergo significant swelling in diameter, leading to increased yarn crimps in the width-wise direction in woven fabrics. The fabrics exhibit advanced stretch and recovery, do not shrink or wrinkle easily and maintain a smooth appearance even after home laundering.

As such, the process offers a synthetic fibre-free alternative for stretch fabrics.

“Our technical innovation unlocks the inherent potential of Tencel lyocell fibres for producing stretch fabrics that move in harmony with the body,” says Rex Mok, vice president of technical fibre marketing and development at Lenzing. “We are committed to fostering responsible production practices through innovations in the textile sector and are delighted to share this latest development with our fabric mill partners. Together, we are taking a significant stride towards reduced usage of fossil-based materials within the textile value chain while ensuring comfort and material performance.”

To go a stage further, Lenzing extends comprehensive support at the fabric development level to mill partners. The stretch fabrics made using Tencel lyocell fibres meet the international standard for fabric stretch and recovery properties. Collaboration with Lenzing will enable mills and brands to unleash unlimited design possibilities while addressing the growing consumer demand for comfortable apparel produced responsibly, particularly in sectors such as sportswear, athleisure garments, loungewear, and home textiles.

Tencel fibres are derived from controlled or certified wood sources and manufactured in a resource-saving closed-loop production process. They are also identifiable in end products and traceable back to their sources, ensuring greater accountability and transparency in the supply chain.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more