Baltex to unveil Advanced Surface Technology innovations at Techtextil

The company’s CEO Charles Wood was upbeat at the exhibition, with a whole raft of new technical fabric developments on display.

29th June 2017

Innovation in Textiles

|

Ilkeston, Derbyshire

Baltex, an Ilkeston, Derbyshire, based company specialised in warp knitting and weft knitting technologies, exhibited a whole range of new product developments at the recently held Techtextil trade fair, which concluded in Frankfurt in May.

The company’s Managing Director and CEO Charles Wood was upbeat at the exhibition, with a whole raft of new warp and weft knitted technical fabric developments on display. “We have no fewer than 17 new developments on show here in Frankfurt,” Mr. Wood said.

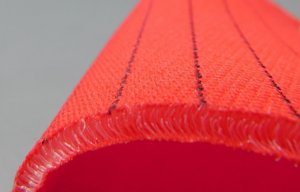

The company has recently launched its latest product development called SARK – a high performance anti-slash fabric that is said to be comfortable to wear. The unique patented material for use in the personal protection industry is said to be relatively light, soft and flexible, whilst providing the necessary protection for a wide range of applications.

“We are particularly encouraged by the interest we have received in our new SARK anti-slash range of fabrics. SARK uses both Kevlar and Dyneema yarns in a specially constructed chevron like structure, which helps deflect sharp objects such as knives and blades,” said Mr Wood.

“The original development was carried out under the guidance of Professor Subhash Anand at the University of Bolton’s Institute for Materials Research and Innovation. SARK was originally created to protect the police, armed forces and security personnel but other areas of application include protection for motorcyclists, hunters, butchers and timber merchants,” he explained.

The novel fabric structure is a two-layer material, which is comfortable to the user and shows similar slash and cut resistance performance when tested on both surfaces, in spite of the fact that two completely different yarns are used to produce the fabric, the company explains. “In police and security personnel applications, protecting the neck area is crucial and we have developed a range of SARK flat knitted shaped collars to that end,” added Mr Wood.

“At Baltex our diverse manufacturing capabilities, technical expertise, and wide experience of fibres, fabric performance, and finishing techniques allows us to engineer the best solutions for a wide range of technical applications,” the company explains. The manufacturer works with partners in industry, education, and research to develop leading-edge customer solutions.

“With an ISO 9001 compliant quality system, in-house performance testing, and a project-driven development programme we are able to assure our fabric quality, and performance, meets the requirements of our customers and end-users.”

In 2010, the company won the prestigious prize for Product Innovation at the Textile Institute's centenary World Conference in Manchester. Baltex was recognised for work it had done on 3D knitted spacer fabrics produced on double needle bar warp-knitting machines under its XD Spacer programme. At the same time Baltex’ Managing Director Charles Wood was awarded the Fellowship of the Institute (C.Text FTI) at a ceremony held in Manchester.

Founded in 1831, Baltex designs, manufactures and supplies a wide range of high performing technical textiles for a range of high performance markets and applies specialist fabric finishing techniques, laminations and coatings. The company supplies advanced materials to industries such as aerospace, military, medical, composites and automotive.

With manufacturing and R&D facilities in both the UK and Eastern Europe, Baltex aims to provide a cost effective and comprehensive service to its wide customer base. In order to support the continually growing range of market sectors for performance fabrics the Baltex Technical Department is constantly reviewing innovative raw materials and new technologies to develop performance fabrics, or customise existing ones based on customer specifications.

Further information

Baltex UK

Tel: +44 (0)115 9322403

Sales email: [email protected]

Office email: [email protected]

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more