New appointments at Brückner Textile Technologies

Customers in Taiwan and China ordered glass fabric finishing lines, among them continuous desizing lines and finishing lines for extremely light fabric.

6th April 2018

Innovation in Textiles

|

Leonberg

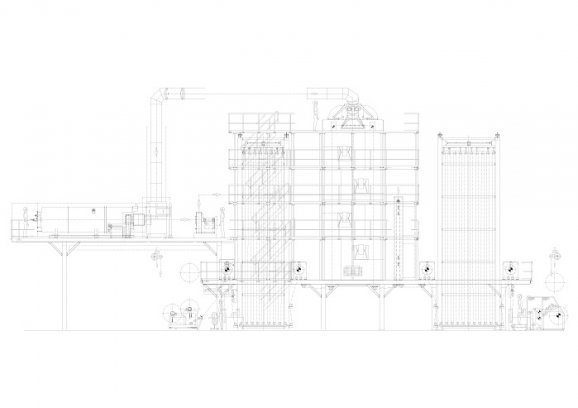

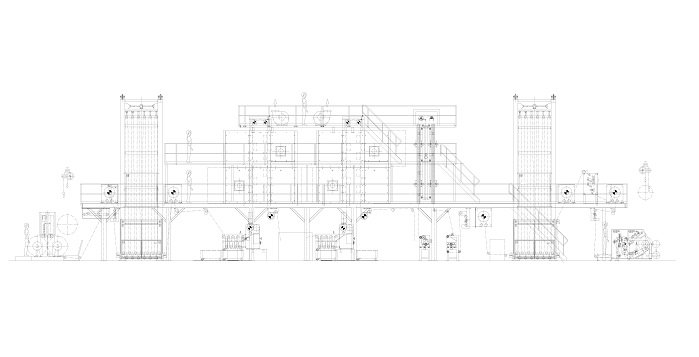

Brückner, a leading producer of finishing lines for the textiles industry, has reported an increase in orders placed for its glass fabric finishing lines during the last 12 months, “exceeding by far all expectations”, according to the manufacturer. Several customers in Taiwan and China ordered glass fabric finishing lines, among them continuous desizing lines and finishing lines for extremely light fabric. Some of the finishing lines were ordered for the universal use with light and heavier fabric weights from 23 to 202 g/m².

The rapid developments in the field of electronics lead to an ever-increasing demand for so-called electronic glass. This glass serves as basic material for printed circuit boards and is used due to its excellent dielectric characteristics with up to 16 stacked layers. The users of modern communication and semiconductor technology expect increasing capacity with lower weight. In reverse this leads to a rapid increase of the demand for electronic glass of the highest possible quality.

“The trend towards lower and lower weights per m² is unmistakable,” the company reports. “Five years ago, a surface weight of 48 g/m² was the standard for producers of electronic glass but in the meantime the standard is approx. 23 g/m². The leading producers in this field dare already to produce and use woven glass with a weight of 12 g/m².”

The extreme yarn and fibre fineness presents, however, a certain limit for the processing of these light woven fabrics. Currently it cannot be assessed if this trend can and will continue. These woven fabrics are disputed among doctors and biologists. Broken filaments of micro dimensions, which do inevitably occur during the processing of the glass fabric, get with the inhaled air into the lungs and from there possibly into the blood circulation.

“The extremely low fabric weight is, however, an enormous challenge for the machinery supplier,” the company says.

“The highest possible precision when controlling minimum tractions, an absolute parallelism in the alignment of guide rollers and fabric accumulators, the use of special acid-resisting stainless steel and highly effective fabric path cleaning technology are just as obligatory as a minimum consumption of electrical energy and process heat and a highly effective exhaust air cleaning according to the latest state of the art.”

Brückner continuously develops its lines for continuous desizing and finishing, suppling its glass fabric finishing lines to well-known producers of electronic glass. These lines are said to produce with the highest possible re-liability on more than 330 days a year and round the clock with fabric speeds of up to 120 m/min.

“This reliability, the high productivity and the possibility to process not only extremely light but also a wide range of fabric weights with the required quality makes Brückner a dependable partner for the producers of electronic glass. Therefore, it is the rule that Brückner is awarded the contract also in case of follow-up orders,” the company concludes.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more