Interview with Adrian Williams, MD, Future Materials Group

Opinion

Latest developments defined by high-rate manufacturing, digital coherence and circularity.

10th December 2025

Adrian Wilson

|

Paris

Each year, the JEC Composites Innovation Awards provide a vantage point on how the composites industry is evolving and the 2026 finalists reveal a sector that is actively redefining its materials and processes.

The 2026 award winners will be announced at the JEC World Premiere on January 12, 2026, in Paris, ahead of the three-day exhibition which takes place at Paris-Norde Villepinte from March 10-12.

Thermoplastics continue to move into demanding structural roles and circularity has progressed from aspiration to credible industrial practice. Across aerospace, automotive, maritime, energy and sport, the year’s selected finalists highlight how collaboration continues to accelerate progress.

Aerospace – Parts

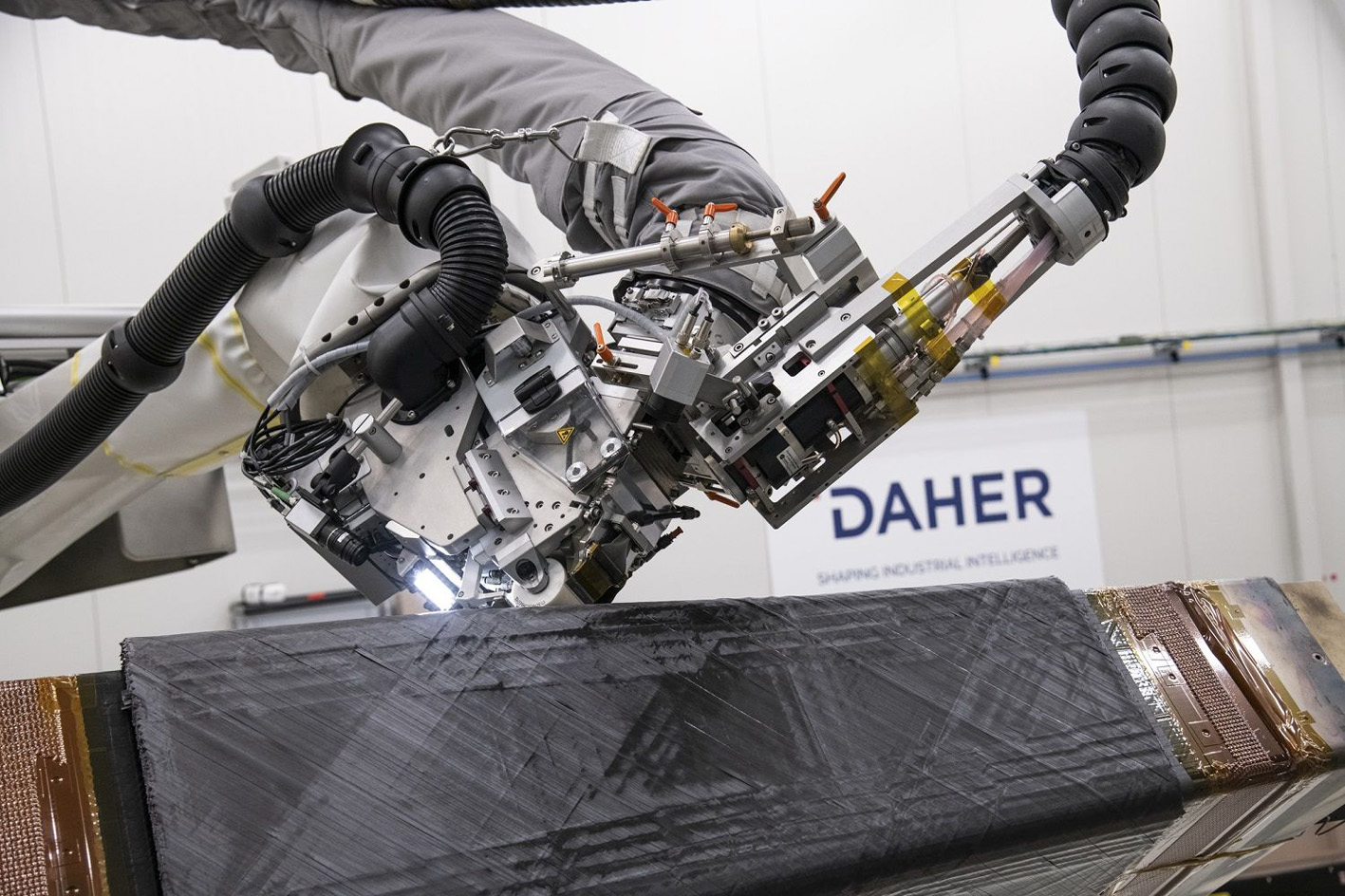

The aerospace parts category showcases both technical ambition and a maturing confidence in thermoplastic composites. In France, Daher has reimagined the traditional metallic wing rib, working closely with the Luxembourg Institute of Science and Technology, Victrex in the UK, Cetim in France and AniForm Engineering in the Netherlands to create a highly loaded thermoplastic rib formed from carbon fibre reinforced LMPAEK.

LMPAEK (low-melt polyaryletherketone) is a high-performance thermoplastic polymer engineered to melt at a lower temperature than standard PEEK (polyetheretherketone) or PAEK (polyaryletherketone) grades. This lower melting point gives manufacturers a wider and more stable processing window, which is particularly valuable in the automated fibre placement (AFP), press forming, stamp forming and welding of carbon-fibre laminates.

LMPAEK maintains the hallmark properties of the PAEK family – toughness, chemical resistance, fatigue resistance and high temperature capability – but offers greater processing efficiency, lower energy demands and improved weldability.

The result, shaped through advanced AFP and infrared welding, achieves the dual objectives of weight reduction and high-rate processing.

Flying Whales, also based in France and collaborating with local partners Hexcel and the Duqueine Group, along with Exel Composites in Finland, has turned its attention to the structural backbone of its LCA60T airship. Together, the partners have devised a rapid, cost-efficient manufacturing route for long composite beams at the production rates required for future airship fleets.

Spirit AeroSystems, headquartered in Wichita, Kansas, has meanwhile demonstrated a fastener-free thermoplastic fuselage panel developed with European partners Corebon, Synesqo and Toray Advanced Composites. By uniting AFP skins with stamp-formed stiffeners through a suite of patented welding processes, the Wichita demonstrator avoids drilling and shimming entirely, pointing towards lighter, cleaner and more efficient fuselage architectures.

Aerospace – Process

Process innovation continues to reshape how composite aircraft structures are designed and manufactured. In the Netherlands, Airborne has implemented its automated ply placement system in partnership with Airbus in Spain, creating a fully automated chain for producing dry-fibre RTM (rapid transport moulding) preforms for the Airbus A350 fuselage. With machine vision, automated cutting and dynamic recipe generation, the system exemplifies the shift towards high-rate automation in aerospace manufacturing.

Germany’s CTC, an Airbus company, has taken a broader systems approach through its Sauber 4.0 initiative. Working with an extensive German consortium that includes research institutes, technology providers and energy-modelling specialists, the programme brings together inductively heated tooling, advanced preforming and a digitalised RTM process designed to support both ecological and economic targets in next-generation wing production.

At Leibniz University Hannover, German researchers collaborating with MD Aircraft, TU Braunschweig and Kasaero have demonstrated the ‘right first time’ manufacturing of bionic, topology-optimised fuselage panels by embedding AFP constraints directly into the design rules. The resulting grid-stiffened panel combines notable weight reduction with a more industrially coherent design-to-part workflow which is particularly relevant for emerging electric aircraft.

Automotive and Road Transportation – Parts

Automotive OEMs continue to widen their exploration of sustainable and thermoplastic composites. In Austria, Engel has developed a hybrid thermoplastic battery enclosure with SABIC, Forward Engineering and Siebenwurst, integrating cooling channels, vents and fastening features within a single moulding operation. The approach improves structural efficiency, reduces CO2 emissions and supports high-rate electric vehicle (EV) production.

In Germany, BMW M GmbH has partnered with Bcomp in Switzerland, SGL Technologies and PPG Wörwag in Germany and Cobra in Thailand to advance flax-based natural fibre composites for both interior and exterior applications. Proven under motorsport conditions and supported by improved resin systems and coatings, the materials offer a substantial reduction in production emissions while aligning with BMW’s wider sustainability strategy.

Volkswagen Group of America, working with the University of Tennessee, Endeavour Composites, Bentley Motors in the UK and WEAV3D, has taken a novel route through paper-fibre-reinforced polypropylene. This composite, strengthened by localised lattice reinforcement, brings finer fibre dispersion, improved mechanical properties and recyclability within the PP stream, suggesting a new class of natural fibre-based materials suited to high-volume interiors.

Automotive & Road Transportation – Process

Manufacturing processes in the automotive sector are evolving just as rapidly. At the Chemnitz University of Technology in Germany, researchers collaborating with Mahle Filtersysteme, Formenbau GF, In2p, Gerlinger Industries, Wickert Maschinenbau and Fraunhofer ICT have devised a fast compression-moulding route for thermoplastic battery housings. It achieves cycle times below two minutes and offers significant life-cycle CO2 reductions compared to aluminium die-cast solutions.

Also in Germany, Gestamp Autotech Engineering, working alongside the Fraunhofer Institute for Chemical Technology, Karlsruhe Institute of Technology, DG Aviation, Koller Formenbau, Toray and Vibracoustic, has developed a carbon fibre SMC (sheet moulding compound) control arm with remarkable weight savings. Enabled by proprietary fibre-cutting and flow-optimisation technologies, the part combines performance, design freedom and digitalised process prediction.

In the UK, Cygnet Texkimp and McLaren Automotive have collaborated on the ART rapid tape-deposition system. By depositing dry-fibre tapes at up to 2.5 metres per second with impressive precision, the system reduces scrap, shortens cycle times and delivers structural improvements already being realised in McLaren’s composite-intensive vehicle platforms.

Circularity and Recycling

Circularity is emerging as one of the most vibrant areas of composite innovation. In France, IDI Composites International has developed a circular recycling route for thermoset SMC liftgates in partnership with Flex-N-Gate, reintroducing up to a quarter of recycled material into new compounds while retaining mechanical performance.

Toray Advanced Composites in the Netherlands, collaborating with Airbus and Daher in France and Tarmac Aerosave, has pursued circularity from an aviation perspective by reclaiming thermoplastic components from retired Airbus A380s and repurposing them into new parts for A320 NEO aircraft. The project demonstrates a credible pathway for high-value aerospace materials at end of life.

Angeloni Group in Italy, working with Sparco, Herambiente and Carbon Task, has established an industrially integrated system for recovering carbon fibres from production waste. By combining pyro-gasification with needlepunching and re-impregnation, the partners produce regenerated semi-finished goods capable of serving in demanding sectors, while offering repeated recycling potential.

Digital, AI and Data

Digitalisation now touches every stage of the composite lifecycle. At Purdue University in the USA, the CompositesAI initiative, developed with AnalySwift, the Applied Research Institute and the IACMI Composites Institute, offers an AI-powered expert system that consolidates standards, analysis and engineering knowledge into explainable answers linked to simulation outputs.

In Australia, the University of Southern Queensland, working with MEMKO, Dassault Systèmes and Boeing Australia, has created a continuous digital thread for the repair and manufacture of composite aerospace structures. The system integrates inspection, automated patch definition, scarfing strategies, manufacturing data and return-to-service validation.

Spain’s AIMEN Technology Centre and partners have demonstrated a composite outlet guide vane produced through AFP and RTM with embedded quality control. The result is a lighter, more consistent component with sharply reduced defect rates.

The project was supported by RTDS Group in Austria, IRT Jules Verne in France, eBOS in Cyprus, the Barcelona Supercomputing Center, GKN Aerospace in Sweden, AMADe at the University of Girona, Instituto Tecnológico de Aragón, Addcomposites in Finland, TU Delft and ESI Group.

Maritime Transportation and Shipbuilding

Composites continue to gain ground in maritime structures that once relied exclusively on metals. Ampelmann in the Netherlands, collaborating with Solico Engineering, Vuyk Engineering Rotterdam, Rondal, Gurit, Lloyd’s Register and Sinteg Systems, has produced a composite telescoping boom for offshore gangways that reduces mass by 30% and lowers operational energy use.

Loiretech Ingénierie in France, working with partners across Greece, Cyprus, France, Bulgaria and the UK, has developed CoPropel, a composite propeller designed to adapt its pitch under load through tailored fibre orientation. Embedded optical fibres and strain gauges provide continuous structural-health monitoring, while an RTM manufacturing route ensures robust edge protection.

Switzerland’s Carbo-Link, collaborating with Foundation in the Netherlands, has redefined the yacht mast as both a structural element and a passive ventilation system. By integrating an internal airflow channel within a one-piece autoclaved mast, the design reduces reliance on mechanical air-conditioning while maintaining the stiffness and reliability expected of superyacht structures.

Pipes, Tanks and Hydrogen

In the UK, TWI has worked with Aramco and Future Pipe to adapt traditional metallic welding concepts for thermoset composite pipes. By applying a thermoplastic coating and uniting rotary friction welding with induction welding, the partners have created a more reliable and less labour-intensive joining approach.

Belgium’s Covess, working closely with Air Liquide in France and Arkema, has pushed pressure-vessel design into new territory with a fully thermoplastic, linerless Type 5 tank, wound from biobased nylon tapes. The vessel is inherently safe under fire conditions, vacuum resistant and fully recyclable, marking a notable advance for lightweight hydrogen storage.

Germany’s CTC, collaborating with AFPT, Argo-Anleg, CompriseTec, DLR, E-Cap Marine, Faserinstitut Bremen, IDVA, the Swiss FHNW, Schunk, Suprem and Teijin Carbon Europe, has addressed the challenge of cryogenic microcracking in liquid hydrogen tanks. Through a considered combination of thermoplastic matrices, optimised lay-ups and manufacturing developments, the LeiWaCo project delivers a demonstrator that could underpin future hydrogen mobility.

Railway Vehicles and Infrastructure

In France, Stratiforme Industries has partnered with EcoTrain to create a fully composite railway cab body that replaces metal structures with a flax and glass fibre architecture. With embedded metal inserts and a vacuum-infusion manufacturing route, the structure achieves dramatic weight savings while maintaining the mechanical and fire-safety performance required for passenger rail.

UK company Composite Braiding has collaborated with Amey, Connected Places Catapult and BCIMO to produce a composite twin-track cantilever for railway electrification infrastructure. Using braided thermoplastic composites consolidated at high speed, the partners have demonstrated an eighty per cent mass reduction and a step-change in installation efficiency.

Brazil’s G12 Innovation, in collaboration with Talgo in Spain, has delivered composite connecting rods for high-speed trains using aramid, carbon and glass fibres in a bio-based resin. The rods offer substantial weight reduction, high fire performance and lower environmental impact compared with traditional metal designs.

Renewable Energies

In Greece, Synthesites has worked with Siemens Gamesa in Denmark to create a sensor-enhanced mould for offshore wind blades with lengths of more than 100 metres. Real-time dielectric sensing provides continuous insight into resin arrival, viscosity, cure state and glass-transition behaviour, reducing curing times and improving process reliability.

CSSI’s FOCUS system, developed with USC–McGill, Alpha Star, American Electric Power and Saint-Gobain Vetrotex, replaces metallic solar mounts with fastener-free composite profiles produced via 3D pultrusion. These modular, robot-friendly structures have enhanced storm resistance.

Turkey’s Metyx, working with Itech Solar and the Middle East Technical University’s Centre for Solar Energy Research, has introduced a composite photovoltaic module for vehicles that replaces glass with a transparent glass fibre composite front sheet and a carbon fibre sandwich back. Lightweight, impact resistant and suitable for curved surfaces, the design broadens the horizon for vehicle-integrated solar power.

Sports, Leisure and Recreation

In Canada, Bespline has collaborated with Gurit, X-Track, Arkema, Red Bull and the Québec Composite Development Centre to create a modular synthetic track for electric motocross, BMX and mountain biking. Using adaptive moulding, recycled rubber, flax fibres and bio-based resins, the system blends sustainability with high performance and straightforward installation.

France’s Toray Carbon Fibres Europe, working with Head Sports in Austria and Delta Preg in Italy, has taken strides towards circular sporting equipment with bio-circular carbon fibres used in the Boom racquet series. Produced from waste-derived precursors under a certified mass-balance framework, the fibres reduce emissions while preserving elite performance.

Germany’s Fenix Composites, collaborating with Alformet, Herone and HyJOIN, has introduced a repairable, recyclable road-bike frame made from thermoplastic carbon composite tubes joined to titanium lugs by reversible induction welding. The design allows damaged components to be replaced without discarding the entire frame, demonstrating how performance cycling can embrace longevity.

A new industrial landscape

Viewed as a whole, the 2026 finalists present a composites sector moving confidently towards a future defined by high-rate manufacturing, digital coherence and circularity. Materials are becoming lighter, tougher and more sustainable, manufacturing is becoming leaner, smarter and more automated and collaboration remains the catalyst that moves innovations from laboratory experiments to industrially viable solutions.

In the last 28 years, the JEC Composites Innovation Awards have attracted more than 2,200 participating companies from around the world.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more