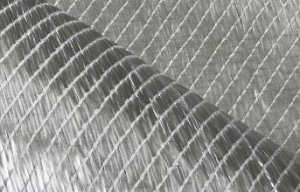

Chomarat unveils new multiaxial glass NCF

The product is said to offer the benefits of both glass and polyester and combine the performances of laid scrim and nonwoven materials in a single layer.

8th December 2015

Innovation in Textiles

|

Le Cheylard

The innovative product is said to offer the benefits of both glass and polyester and combine the performances of laid scrim (strength and dimensional stability) and nonwoven materials (puncture, fire and tear resistance) in a single layer, the company reports.

Rotaflam Neo is the result of a joint development between Chomarat, an expert in the design and production of laid scrim, and Norafin, a specialist in hydro entanglement nonwoven for 35 years.

The reinforcement is made up of a fibreglass and/or polyester-based laid scrim, a nonwoven material and a glass veil. The nonwoven material uses a water-jet binding process that is said to guarantee the performances of the laid scrim.

Using a laid scrim that combines glass and polyester offers two benefits, according to the manufacturer: thanks to its intrinsic properties, the glass adds stability on the roof, but also on the membrane production lines, while the polyester brings elongation and strength.

“By combining our know-how, we can offer a reinforcement that rises to the challenges of the waterproofing market, offering improved performance, while reducing the thickness of the membranes,” the company reports. The reduced weight of the bitumen is said to significantly cut the production costs of the membranes.

The membranes produced with Rotaflam Neo pass the European fire resistance tests (BROOF T1,T2, T3). Rotaflam Neo is designed to improve the fire resistance of the waterproofing membrane and does away with the need to include certain chemical additives in the formulation. This, according to the manufacturer, means that the environmental impact of our solution is also reduced.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more