Boosting precision finishing at Pincroft

Dewatering breakthrough from RHL means textile finishers can finally say goodbye to conventional rubber squeezing

18th December 2012

Innovation in Textiles

|

Bolton

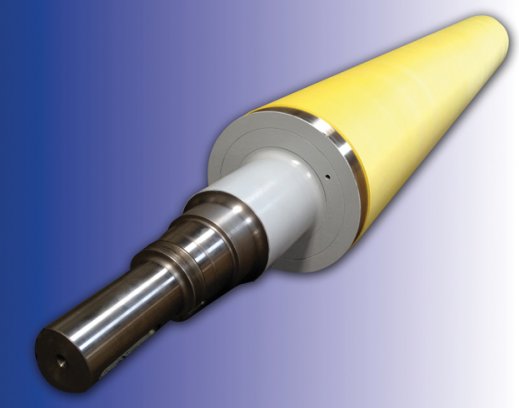

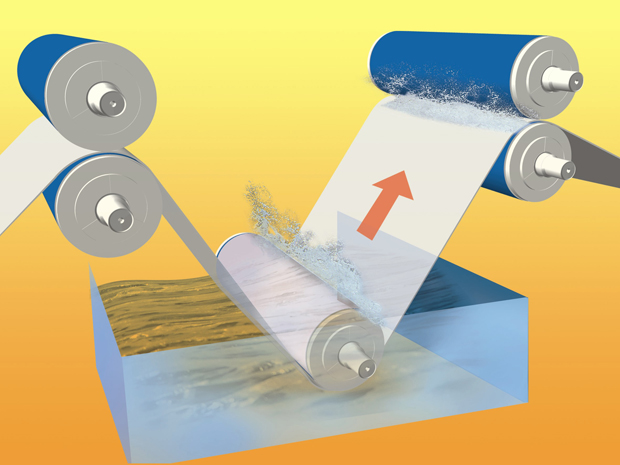

A revolutionary new version of the famed Roberto roll is said to be the first fibre-based squeezing system to offer full resistance to harsh chemicals. The global launch of the RoberteX squeezing roll means that processors no longer have to rely on outdated rubber rolls for water extraction in demanding conditions, according to UK producer Richard Hough Ltd. (RHL).

The innovative RoberteX, now commercially available worldwide, was initially presented at the recent ITME machinery show in India. With its special chemical resistance properties, the RoberteX extends the range of dewatering options offered by RHL to include advanced-technology solutions for every textile squeezing requirement.

Previously, the RHL Resilio rubber squeezing roll was the only option for high water expression with total chemical resistance, but its use is limited to woven and knitted fabrics. The original Roberto roll, hugely popular in the industry for 50 years, offers the versatility to process loose fibres and yarns, but is less able to cope with chemicals and resins.

With the RoberteX, the RHL portfolio now covers all high-expression dewatering requirements, rendering ordinary rubber roller methods virtually obsolete. Says RHL managing director Anthony Ashton: “We now have the complete energy-saving dewatering solution. So we suggest it is now time to declare the traditional rubber squeezing roll well and truly dead.”

The RoberteX fibre roll is said to combine the advantages of chemical resistance with a liquid extraction performance that is 20-30% better than a standard rubber squeezing roll. It can also last ten times longer than standard rubber rolls, for long-term energy savings.

According to RHL, the RoberteX will perform in all aggressive textile processing environments and is the ideal choice for use in harsh caustic or acidic environments with an operating pH range of 0-14. Additionally, by reducing carry-out and cross-contamination, RoberteX can help reduce fluid consumption and cut the cost of waste disposal, the company says.

Anthony Ashton believes the RoberteX is the latest in a series of game-changing innovations by the company, which has a 200-year heritage in the development of calender and dewatering rolls: “This is another revolutionary breakthrough from Richard Hough,” he says. “We have made it our goal to improve the standard rubber squeezing roll, dating back 60 years to the development of the patented Sycotex high-expression squeezing roll made purely from wood shavings, and 50 years ago to the first nonwoven fibre squeezing roll, the Roberto.”

“In 2008 we introduced the revolutionary Resilio rubber squeezing roll, which also gives 20-30% more expression than standard rubber but can also have full chemical resistance. Now, with our launch of the RoberteX fully chemically-resistant fibre roll, we have the complete family of dewatering rolls.”

Despite its widespread use in the industry, RHL says the original Roberto roll has the drawback that it lacks chemical resistance and cannot be used with certain resins, which tend to block its microporous structure. The launch of the Resilio roll combined huge squeezing power with chemical resistance – but this product needs a woven or knitted structure to work its magic, as it releases liquid droplets trapped within the intersects of the fabric. This means it cannot be used on loose stock fibres such as viscose, or on yarns.

Now, the new RoberteX fibre roll completes the RHL squeeze roller trilogy perfectly, as it can be used in a number of important applications where Roberto and Resilio are not suitable.

Says Anthony Ashton: “Some textile processors will prefer to work with a product such as Resilio, because they are more comfortable with the properties of rubber rolls. Others will choose to work with the Roberto fibre roll, and for them the chemically-resistant RoberteX will be a major improvement.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more