Web Industries appoints new Vice President of Sales

TFP’s glass veil is used as the internal separation layers within the insulation patch, an essential part of the thermal management of the satellite.

19th January 2016

Innovation in Textiles

|

Burneside

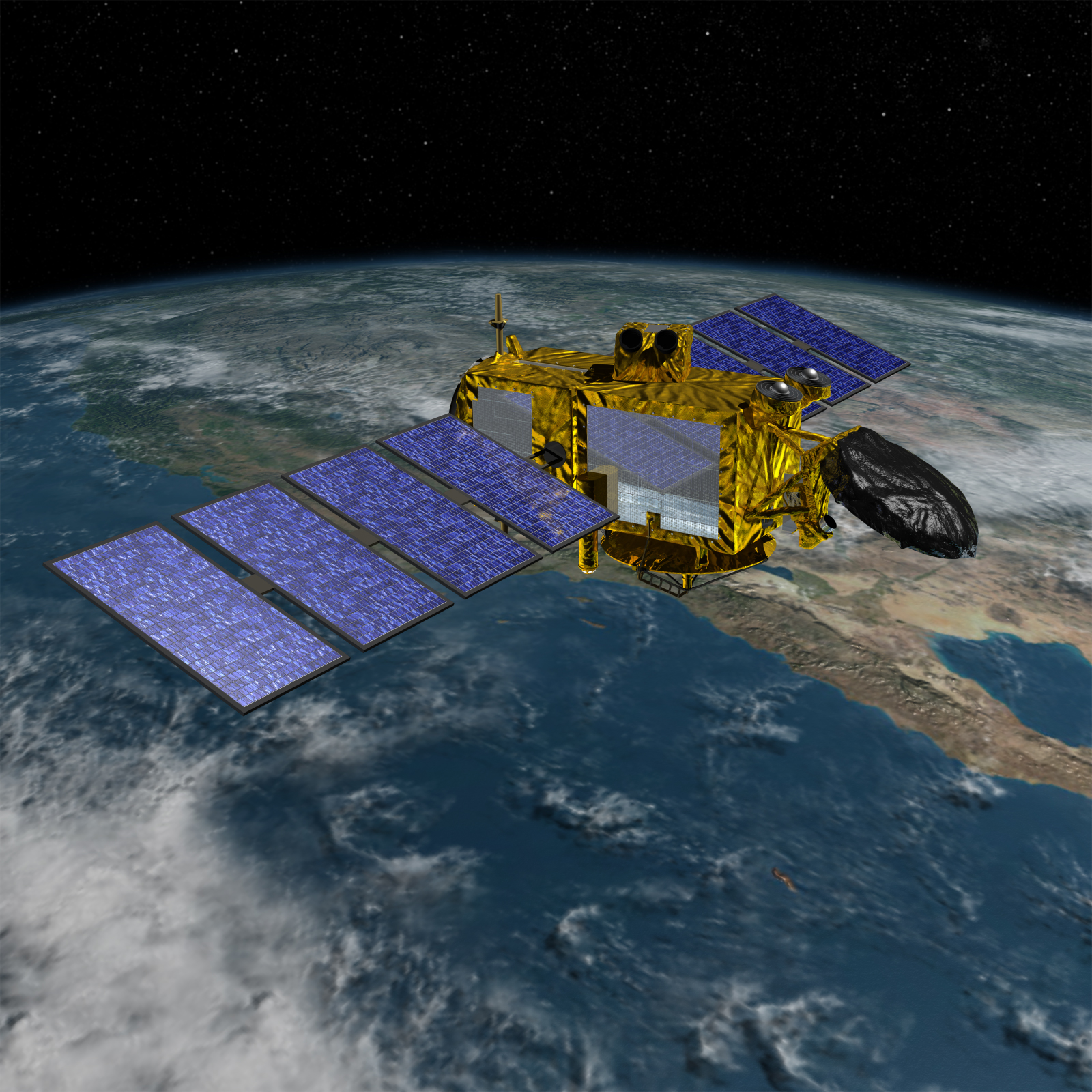

Technical Fibre Products has announced that the company’s advanced nonwovens are present on the recently launched Jason-3 Earth observation satellite.

Technical Fibre Products (TFP) fine glass veil was supplied to NASA’s Jet Propulsion Laboratory (JPL) and can be found in the high temperature insulation patch on the satellite’s Advanced Microwave Radiometer.

TFP’s glass veil is used as the internal separation layers within the insulation patch, an essential part of the thermal management of the satellite. Orbital manoeuvres can temporarily align the sun near the axis of the parabolic reflector of the radiometer. Concentrated sunlight then heats small areas of insulation. The high temperature insulation patch, containing TFP’s veil, is designed to withstand this heating and protect the vulnerable, conventional multi-layer insulation from overheating.

The Advanced Microwave Radiometer is part of the Jason-3 mission and was successfully launched on 17 January 2016. It is the result of a collaboration between NASA, NOAA, CNES and Eumetsat and represents the latest in a series of satellites dedicated to measuring the global sea surface height.

The satellite will make detailed sea-level measurements with a view to gaining greater insight into ocean circulation as well as climate change.

The material used on Jason-3 is just one of a broad range of advanced nonwovens developed and manufactured by TFP. This range encompasses carbon, aramid, glass, thermoplastic and metal coated nonwovens, as well as nonwovens created using more speciality fibres, such as quartz, silicon carbide and pure metals.

TFP’s nonwovens are used across a wide variety of industries ranging from aerospace and defence to automotive, energy, industrial, construction and healthcare. Typical applications for TFP’s materials include delivering a high quality and functional surface finish in composites, as well as offering solutions for passive fire protection, high temperature thermal insulation, cryogenic storage and power generation.

TFP also has extensive experience and product development facilities in order to develop a suitable solution for a specific technical challenge. The latter include a pilot machine, high spec laminator, fibre coating line and nanocoating facility, all of which help to enable both effective material design and scale up from concept to larger scale production.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more