Update on cyber-attack at Picanol

Digital features allow weaving machine operators to amplify their own intuition.

5th November 2021

Innovation in Textiles

|

leper, Belgium

Picanol is introducing the Connect generation of airjet and rapier weaving machines with a focus on connectivity and an increased level of data availability.

The machines feature several new functionalities such as a digitalised gripper stroke setting, gripper tape monitoring, climate control, shed angle measurement and fully integrated power monitoring.

“Following the successful launch of our digital platform PicConnect, we have now released a new generation of weaving machines,” said the company’s vice president of weaving machines Johan Verstraete. “They are loaded with new and never-before-seen functionalities. Not only have these innovations allowed us to make big improvements when it comes to our design principles, but when combined with our new digital platform, they will allow weaving machine operators to amplify their own intuition.”

Smart performance

On the OptiMax-i Connect rapier, for example, Picanol has introduced a lubrication monitoring and temperature sensors. The combined data they provide allows the user to ensure the gripper tapes are in optimal condition for maximum performance. As an option, a gripper stroke measurement sensor is also available. This not only dramatically simplifies the setting of the gripper stroke, but also enables the user to realise higher machine speeds when weaving at reduced widths

Even though it is 25 years since the Sumo Drive concept was launched, it remains the most powerful, versatile and energy friendly machine drive available and has been further optimised with a sheet metal package for lower energy consumption, an optimised oil cooling circuit for a better performance and built-in temperature monitoring.

The Connect machines can also be equipped with a power monitoring module, which allows the user to keep track of the energy consumption of each machine over time. Every Connect machine has a built-in ambient temperature and humidity sensor, which will help to optimise the climate control in the weaving shed at the lowest cost. And as raw material is the biggest cost factor, each machine can also be equipped with raw material use monitoring.

Because the machines have more sensors than ever before, they also generate more data. To enable a fast reaction, the BlueBox control unit has been further optimised. Better heat management guarantees short reaction cycles combined with the long lifetime of components.

To enable a good view of all of the data generated, a special sensor dashboard screen is available in the BlueTouch display – with a simple touch of the screen, the current and historical power consumption, temperature, humidity, material consumption, and – on the OmniPlus-i Connect – the air consumption, can be monitored.

In addition, the BlueTouch display is equipped with an action centre – an electronic logbook where all actions such as maintenance interventions can be logged or scheduled beforehand. The machine manual is now available on the BlueTouch display, and with the context-based help function the help pages related to the operation the user wants to perform appear with one click. The built-in web browser even allows the user to consult tutorial videos on the web to guide them through a setting procedure.

Intuitive control

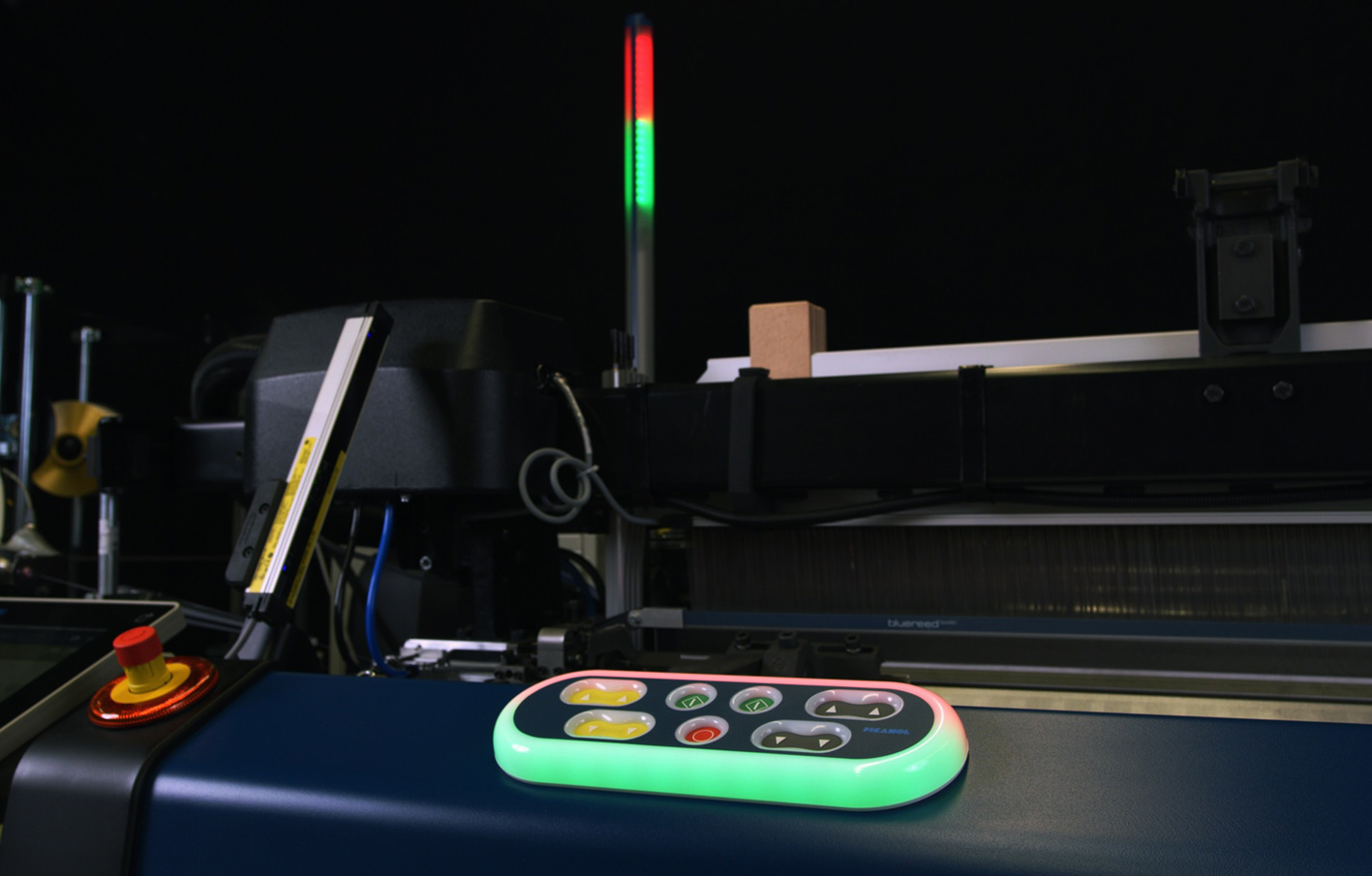

The Connect generation was designed to focus on what really matters – weaving the highest possible grade A fabrics at minimal costs. A large set of tools have been installed to facilitate this goal. One of the most remarkable is the harness frame stroke measurement. Until recently, it was only available on the SmartShed, but is now also available on the cambox and dobby machines. Combined with the shed visualisation and simulation, it provides a quantum leap in terms of optimising the user’s shed settings without losing any time or taking any risks. The colours of the programmable smart signal lights with stop timing functionality are now repeated around the push buttons, allowing even better visibility and the prioritisation of interventions by the weaver. A full-fledged access control system not only limits the access to certain pages and settings depending on the user, but also allows a tailored dashboard to be established for each user profile.

In combination with the new Connect digital platform, the Connect machines will help users jump immediately to the next level of intuitive weaving.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more