Coloreel enters sewing industry with Juki America

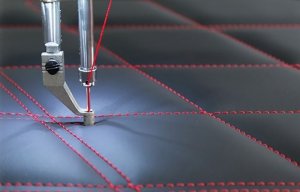

Unlimited colour and design possibilities for quick turnaround, customisation and small-batch production.

17th July 2023

Innovation in Textiles

|

Vietnam

Hwaesung Enterprise, an industry-leading footwear, headwear, and textile manufacturer and a key supplier to brands such as adidas, Lacoste, Nike and Titleist, has installed Coloreel technology at its plant in Vietnam.

The technology eliminates pre-coloured thread, significantly reducing the water and chemical consumption associated with dyeing. By dyeing a 100% recycled polyester thread in real-time, water consumption is reduced by at least 97% compared to traditional dyeing methods. In addition, the technology significantly reduces thread waste.

The aim in the development of Coloreel technology was to streamline an industry characterised by slow processes, difficulty in creating complicated designs and excessive resource usage.

“By partnering with Coloreel, we are taking a significant step towards a more sustainable future while offering our clients unprecedented customisation options,” says Darren Hamilton, executive COO of apparel and accessories at Hwaesung. “This collaboration reinforces our commitment to innovation and environmental leadership.”

“This partnership with Hwaesung, which produces over 20 million hats annually, can truly be a game-changer,” adds Coloreel CEO Torbjörn Bäck. “With unlimited colour and design possibilities, we offer a solution for quick turnaround, customisation and small-batch production, providing significant value to our customers.”

Combination option

In separate news, combining Coloreel embroidery thread with traditional threads has become much easier thanks to the company’s latest software option.

While Coloreel offers improved efficiency and enhanced colour options for most producers, creating certain designs with special effect threads, such as frosted, metallic or neon colours, has had limitations. Similarly, for larger areas of plain white or black, it is still cheaper to use a basic thread than Coloreel’s dyeing process.

The updated software includes Coloreel’s stitch count feature, ensuring that the embroidery machine can stitch the design accurately and consistently, regardless of whether Coloreel or traditional threads are used.

Using the multi-thread option has several benefits, including cost savings over time, as less thread and ink are used, and the ability to create even more intricate designs.

“This update expands Coloreel’s technology capabilities and opens up new possibilities for embroidery producers,” says Mattias Nordin, Coloreeel SVP of product management.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more