Karl Mayer acquires AEI technology

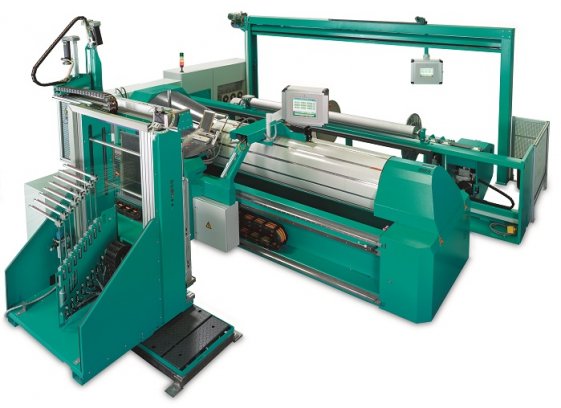

The GIRO-O-MATIC 24 and the MULTI-MATIC 128 sample warping machines and the NOV-O-MATIC have proven to be real bestsellers.

20th July 2016

Innovation in Textiles

|

Obertshausen

Italian textile sector has been enjoying growth and expansion over the recent years, with a focus on premium fabrics and high-ends brands, according to Karl Mayer, a leading warp knitting machinery manufacturer.

The Germany based company’s Warp Preparation Business Unit has also spotted this trend for expansion and renewal, with Karl Mayer’s warp preparation machines becoming bestsellers on a booming market.

By focusing on flexibility, rapid delivery times and customised solutions, Italian textile companies, and weavers in particular, are relying on innovative production technology, such as the Karl Mayer’s warp preparation machines. As a result, the manufacturer reports that its order books are full. “Even in 2014, we could see an increase in orders, but the real boom started in 2015, and will probably continue until 2016,” explained the Sales Manager, Giuseppe Moretti.

Italy represents elegance and exclusivity in fashion like no other country, and this southern European country still heads the top price bracket. Premium Italian fabrics enjoy an excellent reputation, and are finding new customers in the emerging economies, where great importance is attached to high-end brands. The national sector is confident that it can expand its position on the world market over the next few years, as well.

The country’s clothing and textile industries have profited from the pickup in demand in Russia, and have been investing again for some time now – much to the delight of global machine manufacturers. Between 2014 and 2015, German textile machinery exports to Italy did rise slightly, from EUR 72,538 million to EUR 72,647 million, but the signs are that the situation in Italy will start to improve even more, the company reports.

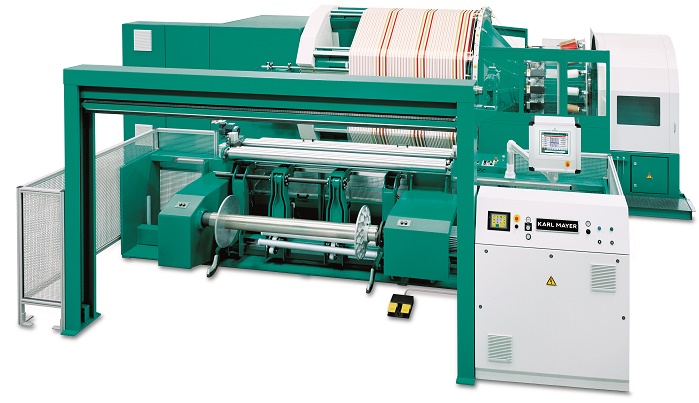

The GIRO-O-MATIC 24 and the MULTI-MATIC 128 sample warping machines and the NOV-O-MATIC automatic, short-warp sectional warping machine have proven to be real bestsellers. According to Giuseppe Moretti, the reason why customers are so interested in these innovative machines is their high operating speeds, beam quality, and their advantages in terms of the number of operatives needed to operate automatic systems.

These machines are in especially high demand in the weaving cluster located in the province of Biella. Since the 13th century, the wool and weaving sectors have been particularly important in this region in the north of Italy. Nowadays, Biella is synonymous with quality on the market for high-end men’s outerwear.

Karl Mayer customers here include well-known brand name suppliers like Vitale Barberis Canonico, based in Pratrivero, Reda Successori, based in Valle Mosso, Loro Piana in Quarona, Ermenegildo Zegna in Trivero and the Marzotto Group, which operates in various locations in the Biella region.

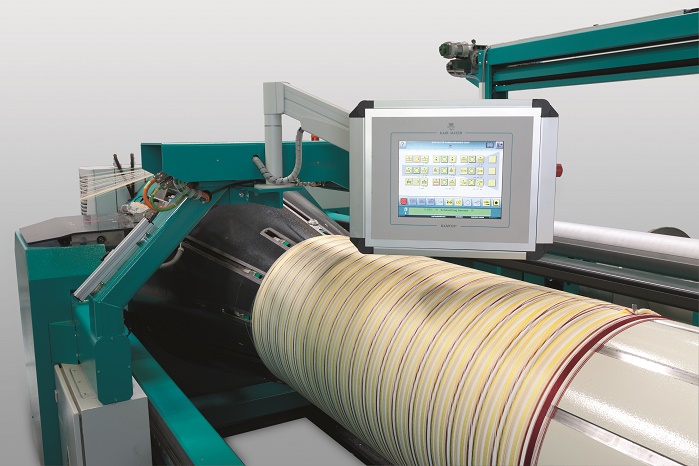

The NOV-O-MATIC fully automatic sectional warping machine is said to be perfect for producing sample and production warps of average length. On this machine, the dividing cords for weaving or sizing are drawn in fully automatically and the feed rate is determined automatically by a laser feed control device (LVR).

The MULTI-MATIC and GIR-O-MATIC machines also operate fully automatically. They can be used both as sample as well as production machines – with different warp lengths in each case. The GIR-O-MATIC 16 is ideal for producing beams having warp lengths of 14 m up to a maximum of 700 m, the GIR-O-MATIC 24 up to 1,050 m, and the MULTI-MATIC from 35 m to a maximum of 1,500 m.

For patterning, the yarn guide fingers can be activated individually, i.e. 16 or 24 on the GIR-O-MATIC and up to 128 on the MULTI-MATIC. The colour can be changed automatically in both cases, with accurate yarn laying at maximum production speeds. The output of the MULTI-MATIC compared to current sample warping machines has been increased by a factor of eight when processing single-colour warps and by a factor of four when processing pattern warps, the company reports. The warps may be up to 40% longer.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more