Brewed Protein – a new seasoning for tailors!

Industrial-scale plant scheduled to begin production later this year in Thailand.

9th September 2021

Innovation in Textiles

|

Yamagata, Japan

Biomanufacturing start-up Spiber, the developer of Brewed Protein materials based in Yamagata, Japan, has raised JPY 24.4 billion through an equity investment round which includes leading global investors such as Carlyle, as well as existing shareholders such as Cool Japan Fund. Spiber has simultaneously approved an additional JPY 10 billion capital raise bringing the total to JPY 34.4 billion.

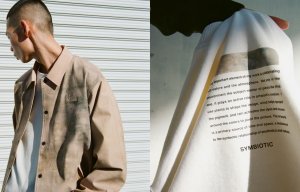

Brewed Protein materials are produced from plant-derived biomass using a proprietary fermentation process and can be processed into a variety of forms, with examples ranging from delicate filament fibres with a silky sheen to spun yarns that boast features such as cashmere-like softness or the thermal and moisture-wicking properties of wool.

Spiber’s in-house technology allows for the production of animal-free fur and leather alternatives, and Brewed Proteins can also be processed into resins closely resembling tortoiseshell or animal horn. With potential uses ranging from medical applications to lightweight composite materials, they are highly adaptable.

Designed to be non-reliant on petrochemicals as primary feedstock, and to not create or break down into environmentally-persistent microplastics, Brewed Protein materials have considerably less impact on marine ecosystems when compared to traditional plastic materials. The unique microbial fermentation technology employed also shows considerable potential for avoiding the high greenhouse gas emissions often associated with commonly-used animal fibres.

Prototype products based on Brewed Protein have so far been pioneered by The North Face, with the Moon Parka, and the Vision Quest blended wool sweater for Japan’s Goldwyn.

After more than 15 years of research and development, Spiber is now focusing on the transition to mass production. Its Thailand plant, currently under construction, is scheduled to begin commercial operation later this year with an annual capacity of several hundred tons.

In Iowa, subsidiary Spiber America will combine its technology with ADM’s deep expertise in large-scale fermentation technologies, engineering, operations and extensive agricultural supply chain. The two companies have started to modify and expand equipment at ADM’s bioprocessing biorefinery in Clinton.

The Brewed Protein polymers will be produced by ADM in the US using plant-based dextrose as a feedstock, and then shipped to Spiber’s downstream facilities, where they will be processed into an array of materials – primarily fibres – for use in a variety of applications.

As a new investor, Carlyle has made a significant investment into Spiber, representing Carlyle’s first-ever non-buyout growth investment in Japan. Spiber will be able to fully leverage Carlyle’s global industry experience, sustainability expertise, and network with luxury brands as well as the textile and material industries to accelerate its further growth. Carlyle’s previous investments include sustainability-oriented companies such as Jeanologia and Beautycounter, as well as world-leading apparel brands like Moncler and Golden Goose.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more