Heberlein at GTTES in Mumbai

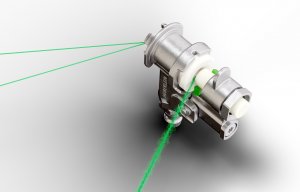

Unique four-sensor technology combined with an intelligent clearing algorithm.

11th May 2022

Innovation in Textiles

|

Pakistan

A total of 5,500 Loepfe yarn clearers are already integrated into the spinning operations of Kohinoor Textile Mills (KTML) in Pakistan, and a first 1,112 of the company’s winding units are now being fitted with the latest YarnMaster Prisma yarn clearer generation.

KTML has nine separate spinning operations with a total of 180,000 spindles covering the complete range of coarse and fine count yarns from natural to man-made fibres and is known for its consistent yarn quality.

“Loepfe yarn clearers have helped us to improve the appearance of our yarns and increased customer satisfaction,” said Muhammad Irfan, general manager of KTML’s plant in Gujar Khan. “We are delighted to continue our relationship by installing YarnMaster Prisma on our lines and we are already seeing the benefits of this new leading-edge sensor technology.”

With the Prisma units, KTML is achieving a new level in yarn quality as a result of a unique four-sensor technology combined with an intelligent clearing algorithm. Of specific importance for the company’s compact ring yarn production are the additional fine classes of SFI/D (surface variation) and OffCount clearing. The refined matrices simplify the settings and provide flexibility to adapt the clearing curve to all market needs, ensuring compact spinning operatives are given the best yarn structure overview of the yarn that is being produced.

KTML uses the unique feature based on the continuous monitoring length of 80 metres for SFI/D clearing and 50 metres for OffCount clearing. Removing long faults in one piece delivers significant advantages including certainty in yarn quality, since no remnants of longer faults are further processed. Other yarn clearer models cut longer faults on their set curve and can as a result slice faults into pieces.

“KTML is a vertically integrated set up producing yarn for its own requirements and at the same time selling in the local market,” said Jahanzaib Baloch, general manager of the company’s Rawalpindi plant. “Finished goods are sold to world-famous brands in the US and Europe and quality is ensured in each and every step. The export market is very sensitive to contamination and to avoid this Loepfe and its Indian partner Service Traders have been our partners for decades. Prisma is an excellent product making it possible to optimise production at the deepest level, with a world full of opportunities in a single sensing head.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more