Arville achieves ISO 14001 certification

Made2flow makes a personalised calculation based on a high level of primary data.

9th August 2022

Innovation in Textiles

|

Cologne, Germany

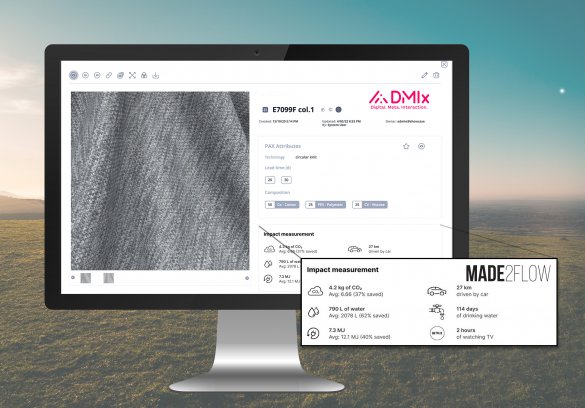

Made2flow’s environmental impact measurement solution is offered as a new, optional module to DMIx, the interactive collaboration platform developed by ColorDigital of Cologne, Germany.

DMIx can now offer brands the ability to seamlessly source fabrics and trims according to their environmental impact, supporting their preferred material strategy

With the addition of this new Made2flow plugin, impact measurement (CO2, water usage, land use and more) can be tracked based on a scientific data analysis, LCA framework, ReCiPe midpoint calculations. The environmental impact is measured across the supply chain, unlocking fabric data and its suppliers (Tier 2 and beyond). The technology will deliver a personalised environmental impact calculation based on a high level of primary data, identify impact hotspots across the supply chain and ultimately empower designers to opt for low impact products.

Both companies deliver solutions that help the industry become more sustainable and reduce its environmental footprint through digital automations, unique data validation technology and standardised data collection.

DMIx is a unique ecosystem offering seamless digital interaction between brands and suppliers in the fashion and lifestyle industry.

The platform enables all stakeholders to transform from physical to virtual collection development with real-time digital exchange of designs, using technology that reproduces colours and textures as close to reality as possible.

Offering digital twin technology, human avatars and real-time master data, DMIx enables collaboration with major design software applications and PLM solutions.

This not only reduces costs and time in the product development process but also minimises environmental footprint by controlling lab dipping and bulk production, reducing the vast number of samples and prototypes traditionally used.

The software-as-a-service solution creates new digitized levels of interaction and collaboration between brands and suppliers, encouraging full product transparency and quality in a colour-and appearance-controlled environment. ColorDigital works with over 300 customers in the textiles, paint, plastics, dyeing, printing and packaging markets is devoted to support sustainable development and workflows for a better industry.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more