Combining the benefits of polyester and nylon

Solotex bicomponent PTT yarns exploited to provide more than just stretch.

1st September 2025

Innovation in Textiles

|

Japan

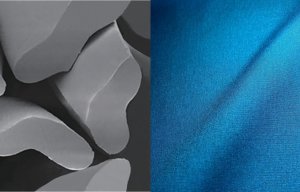

Teijin Frontier has developed a next-generation stretch fabric with an extra-fine three-dimensional structure enhanced by randomly sized crimps.

The newly-developed fabric is said to combine exceptional elasticity with a soft, airy texture and a natural uneven surface that helps make the fabric lightweight while providing quick drying and moisture wicking performance.

Teijin Frontier plans to initially launch the fabric for the outdoor and sportswear markets during the Autumn/Winter 2026 season and then expand its applications to include lifestyle apparel such as innerwear and fashion garments, targeting sales of 100,000 metres in 2026 and one million metres in 2029.

Traditionally, stretch fabrics used in sportswear, fashion and innerwear have relied on polyurethane which presents challenges in terms of strength, durability, weight and colorfastness. Teijin Frontier has previously addressed these issues by developing various stretch materials using Solotex fibre which is made from polytrimethylene terephthalate (PTT).

In recent years, however, consumer demand has evolved beyond stretchability alone and today there is growing interest in fabrics that offer novel textures and appearances, along with gentle-touch comfort. Existing Solotex-based materials provide numerous benefits, but are not fully meeting these new expectations from consumers.

In response, Teijin Frontier leveraged its advanced PTT spinning and drawing technologies to develop an extra-fine side-by-side conjugate yarn that is produced by bonding two different PTT polymers in parallel. It features an extremely fine denier and strong, large crimp structure for excellent stretch performance. Using proprietary yarn processing techniques, this core yarn is combined with high-multifilament polyester fibres to create a sheath-core composite yarn with randomly sized crimps. When woven into a high-density textile, the result is a fabric with a natural, finely textured surface that delivers a light, airy texture and a soft feel.

The contrast in crimp structures between the core and sheath yarns creates a natural, uneven surface with moderate firmness and drape and a soft, airy feel. The fabric also offers excellent moisture absorption and quick-drying properties, and its fine and uneven surface helps prevent stickiness during perspiration.

The core yarn further includes plant-derived raw materials and the sheath yarn uses recycled polyester.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more