Uster in Frankfurt and Istanbul

The manufacturer will demonstrate the importance of the nonwovens sector for Uster Jossi systems at the forthcoming INDEX17 event.

8th March 2017

Innovation in Textiles

|

Uster

A total of 3,500 Jossi fibre cleaning systems – now produced by Uster, a leading high-technology instrument manufacturer – has been installed to date to help yarn spinners prevent contamination in their products. The Uster Jossi Vision Shield solutions, in particular, are said to be highly effective at removing even the smallest contaminants, including polypropylene, the company explains.

The manufacturer will demonstrate the importance of the nonwovens sector for Uster Jossi systems at the forthcoming INDEX17 event, which will take place in Geneva, next month. Uster believes that its technology, which is already used in cotton spinning, will attract wider interest at the exhibition from manufacturers of bleached cotton and other quality-critical nonwovens products.

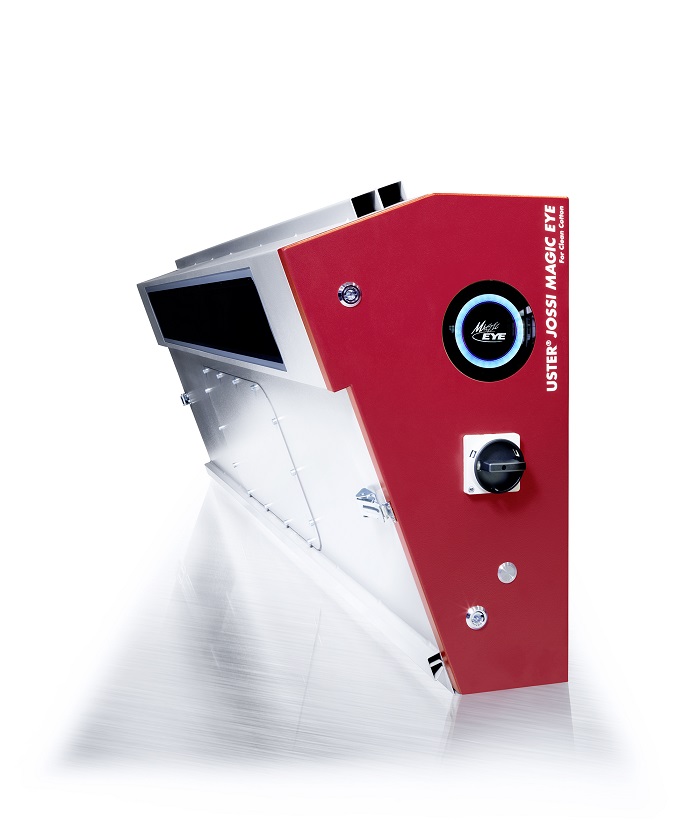

“With Uster Jossi Vision Shield and Uster Jossi Magic Eye, the whole production is checked, for every category of contaminants including synthetics,” said Oswald Baldischwieler, Product Manager Fibre Cleaning within Uster Technologies. “Nothing can escape the detection power of these systems.”

Contaminated yarn is one of the spinner’s biggest headaches, potentially leading to customer claims and rejects when synthetic particles such as polypropylene (PP) remain undetected in cotton until the fabric reaches the dyehouse. For nonwovens producers, the risk of contamination is especially great: in medical and hygiene applications, for example, quality standards are super-critical and zero contamination is essential.

Uster Technologies acquired Jossi AG in 2013 and now applies the Uster Jossi Vision Shield 2 and Uster Jossi Vision Shield T systems, using multiple detection principles to eject all polypropylene particles, however minute. The finest white PP contamination is reliably and efficiently detected with the Uster Jossi Magic Eye in combination with the Uster Jossi Vision Shield. Practically all types of foreign matter, including polypropylene and polyethylene, are eliminated, with a minimum of waste.

“Compared to yarn spinning, nonwoven products and processes bring some special challenges and even more demanding requirements,” the company explains. “Imagine, for example, a scratchy remnant of polypropylene in a make-up removal pad or any kind of contamination in hospital products such as absorbent cotton, alcohol swabs, or nonwoven gauze. Such problems would be totally unacceptable. Not surprisingly, markets for medical and hygiene products in the USA, Europe and Asia are extremely quality-oriented.”

With developments in synthetic fibres, there was a trend about 25 years ago for nonwovens applications to switch from pure cotton to synthetics. Initially, consumers preferred the dry and light texture of synthetic fibres. In the last decade, however, many applications are seeing a return to pure cotton as the favoured option, particularly where allergenic reactions, such as skin reddening and irritation, are an issue.

Manufacturers of nonwovens for these demanding end-uses now require an efficient contamination control system, guaranteeing a zero-tolerance standard – for defects bigger than 1 mm – in their products. In nonwovens, fibre cleaning is the only way to control contamination – unlike in spinning where yarn clearing can make a final check at the winding stage. Product quality in nonwovens, therefore, depends on the efficiency of the fibre cleaning system.

Most of the machinery for nonwoven hygiene products is made by Japanese companies and Japan itself plays a leading role in manufacturing goods for medical and cosmetic applications, as well as food packaging materials.

“Japan is growing as a market for Uster fibre cleaning systems, thanks to these nonwovens applications,” said Oswald Baldischwieler. “The combination of Uster Jossi Vision Shield and Uster Jossi Magic Eye supports the manufacturers to control contamination continuously at a high level.”

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more