SGL Group awarded for joint work

The new product for high-quality textiles is said to improve the softness of textiles, as well as retain the ability to absorb water.

8th June 2016

Innovation in Textiles

|

Munich

Wacker, a Munich based chemical company, has launched an innovative hydrophilic fabric softener for factory textile finishing, called WETSOFT NE 750.

The new product for high-quality textiles is said to improve the softness of textiles and at the same time retain the ability to absorb water. According to the manufacturer, this is particularly important for towels and materials that need to remain absorbent after finishing.

The silicone fluid formulation is marketed as a water-free concentrate, which needs to be diluted with water to produce a ready-to-use emulsion. The main constituents of WETSOFT NE 750 are block copolymers based on aminofunctional silicones and polyglycol.

The silicone fluid segments arrange themselves in free-moving loops on the outside of the fabric and reduce friction between the fibres. This is said to provide the fabric with an excellent soft feel, which even remains after washing. The polyglycol segments, on the other hand, aim to ensure that the silicone finish, which is normally water-repellent, remains permeable to water.

The combination of softness and water absorbency is of crucial importance for high-quality textiles, the company reports. According to the tests conducted by the manufacturer, materials treated with WETSOFT NE 750 have a pleasant, soft and full hand feel while remaining absorbent. As a result, they quickly take up moisture from skin and hair.

This is due to the fact that the emulsion is designed to penetrate to the core of the fabric, even when the fabric contains long pile fibres.

Compared to conventional fabric softeners, the special molecular architecture of WETSOFT NE 750 facilitates water uptake and, at the same time, significantly increases absorbency. From a textile manufacturer’s point of view, it is important that subsequent textile corrections, such as re-dying of the material, can easily be made after the textile has been treated with the product.

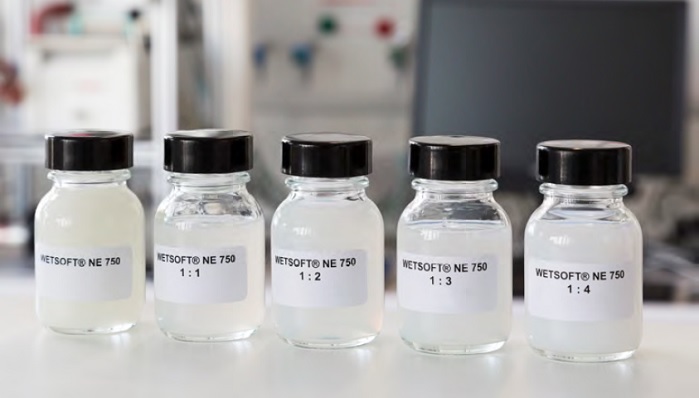

According to the company, the new product offers significant advantages for textile-auxiliary formulators. The hydrophilic fabric softener is marketed as a water-free concentrate with a high solids content. The product is self-emulsifying and can be diluted with water in a ratio of 1:1 to 1:5 to form a stable emulsion, which makes the product easy to formulate.

Users obtain a stable emulsion that combines the typical product benefits of a microemulsion and a macroemulsion. The hydrophilic fabric softener can be applied to towels, woven textiles or knitted fabrics by either exhaust or padding processes. Both cotton and blended fabrics containing polyester can be finished with the product.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more