Magnetic attraction of the Montex Coat from Monforts

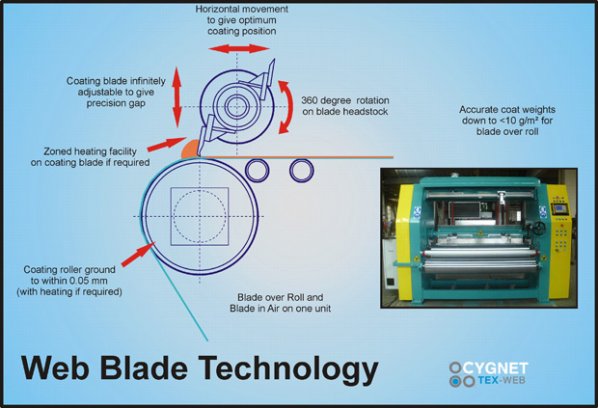

Coating and laminating engineering specialist Cygnet Tex-Web has unveiled a blade over roller machine designed to deliver exceptionally low coat weights of 10 gsm.

13th February 2013

Innovation in Textiles

|

Northwich

Coating and laminating engineering specialist Cygnet Tex-Web has unveiled a blade over roller machine designed to deliver exceptionally low coat weights of 10 gsm.

The company, which was formed by the merger of Texkimp and Web Processing in September 2012, says it has transformed traditional blade coating technology into a high-precision coating solution to create lightweight, high yield performance composites for a range of markets including medical, marine, aeronautics, automotive, work wear and household textiles.

“Blade coating technology is a proven concept in the coating market, but previously its applications were limited because traditional machines were only able to achieve coat weights of 80-100 gsm,” explains Mark Smith, Commercial Director of Cygnet Tex-Web.

“Our engineering team has revisited the origins of the technology and redeveloped it with a series of critical adjustments that have transformed it into an extremely viable solution that offers substantial, tangible benefits to a range of markets.”

Cygnet Tex-Web’s Web Blade Technology features a precision-ground steel roller and blade which are heated before being ground at the temperature of use to eliminate any inaccuracies. An innovative zoned heating system allows accurate temperature control across the width of the steel blade during use and ensures very fine layers of hot-melt coating can be applied to create products with good surface finish and weight uniformity.

Versatile tension controls on the unwind and coating head keep the textile tension constant and ensure accurate, uniform coating, while the angular rotation of the blade can be fine-tuned depending on the application, to deliver exactly the right amount of coating onto the substrate.

According to Cygnet Tex-Web, applications include aeronautical and automotive products as well as medical plasters and bandages, boat and yacht sails, recyclable carpet backing, mattress ticking, vehicle airbags and flame-retardant work wear.

A growing company, Cygnet Tex-Web announced in November 2012 it had won a £5m contract to supply five PAN precursor creels to Jiangsu Hengshen Fiber Materials Co, one of the largest carbon fibre and composites manufacturers in Jiangsu Province, China. The specialist creels with integrated handling equipment, which are manufactured under Cygnet Tex-Web’s Texkimp brand, will be used to unwind and guide PAN fibre from 250kg packages into carbon fibre production lines which will be producing fibre for the aerospace, automotive, marine, rail, renewable energy and industrial markets in the Asia-Pacific region.

The recently formed Cygnet Tex-Web company combines over 80 years of experience designing and manufacturing engineering solutions to process fibre and fabric for uses including tyre cord, plane engines and high performance clothing.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more