New benefits with latest Kevlar EXO aramid

Kevlar, a para-aramid synthetic fibre, is most commonly associated with bullet-proof body armour, yet it offers limited cut and stab protection.

17th September 2014

Innovation in Textiles

|

Cambridge

According to an article published recently by The Royal Society of Chemistry, US scientists have synthesised an ultrathin inorganic bilayer coating for Kevlar that could improve its stab resistance by 30% and prove invaluable for military and first-responders requiring multi-threat protection clothes.

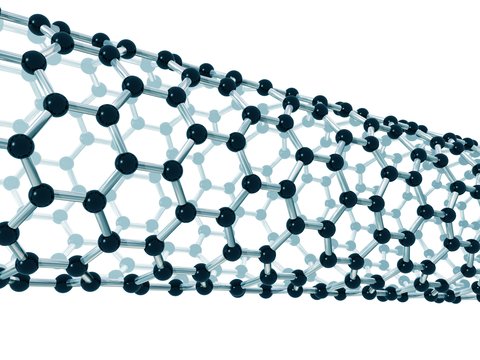

Developed in 1965 by Stephanie Kwolek at DuPont, poly (p-phenylene terephthalamide) (PPTA), or Kevlar, is a para-aramid synthetic fibre deriving its strength from interchain hydrogen bonding. It finds use in flexible energy and electronic systems, but is most commonly associated with bullet-proof body armour.

The report goes on to say that despite its anti-ballistic properties, Kevlar offers limited cut and stab protection. In a bid to overcome this drawback, Sarah Atanasov with her colleagues, from Gregory Parsons’ group at North Carolina State University, have developed a TiO2/Al2O3 bilayer that is said to significantly enhance the cut resistance of Kevlar fibres.

The coating is added to Kevlar by atomic layer deposition, a low temperature technique with nanoscale precision.

Achieving multi-threat protection usually means donning multiple protective layers. “We want to reduce the burden of protective equipment,” said Atanasov.

Despite its increased hardness over both titania and PPTA, alumina is said to have a negative effect on cut resistance if used alone.

When introduced, its tetramethylaluminium (TMA) precursor diffuses and reacts beneath the surface of the PPTA. This degrades the mechanical strength of the polymer by cutting through its backbone and breaking bonds.

In contrast, the titania layer is formed by titanium tetrachloride reacting near the polymer surface, which has little effect on the backbone. It must therefore be introduced first to act as a barrier between the TMA and PPTA. This synergistic relationship between the metal oxides is essential to the overall success of the coating.

Materials specialists are enthusiastic about the work. Takashi Uemura, from Kyoto University in Japan, finds it interesting that one can add armour to Kevlar to improve its protective properties.

Bin Ding, of Donghua University in China, says the most interesting result is that Kevlar sees noticeable improvements without substantially affecting its durability, flexibility or weight. Other techniques have made concessions in at least one area.

Efforts are now underway to test this coating on a larger scale and the group has high hopes that their findings can one day be applied to protective garments.

Business intelligence for the fibre, textiles and apparel industries: technologies, innovations, markets, investments, trade policy, sourcing, strategy...

Find out more